Description

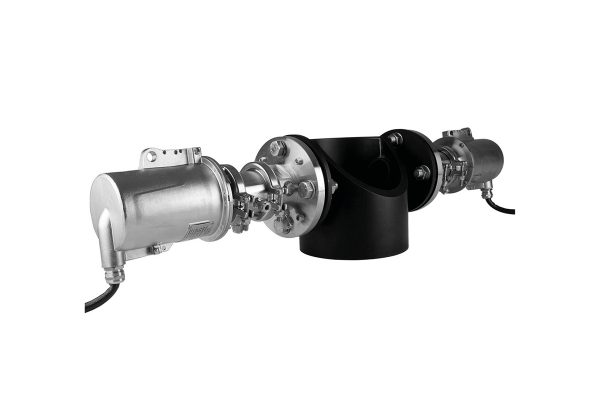

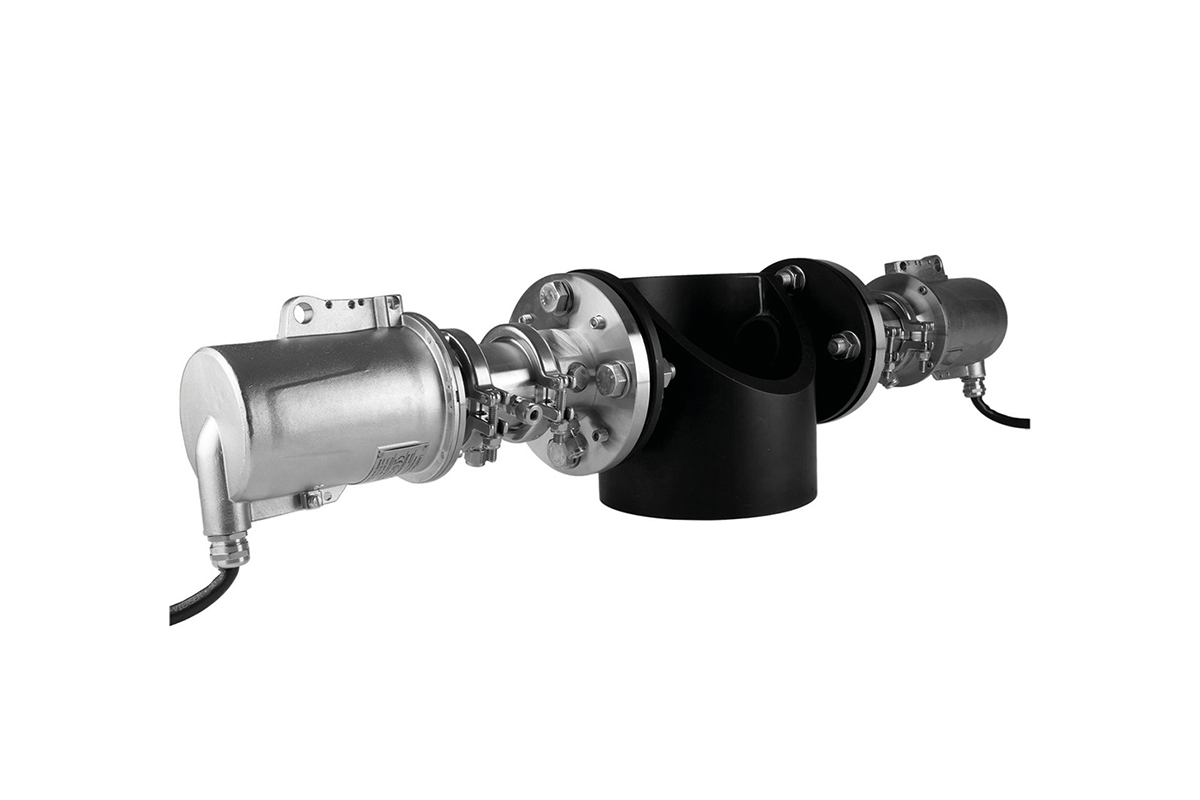

Technical Description – LaserGas™ III SP

Features

- Compact design

- Low detection limit

- Flame proof enclosure

Gases

- NH3

- O2

- O2 + temp.

- CO

- CO + CH4

A Closer Look

- In-situ real time measurements

- Fast response time

- Compact design

- Low power consumption (< 10W)

- TDLAS technology

- Low detection limit

- No interference from other gases

- Automatic gain

- Lifetime calibration, no zero drift

- Integrated span check

- Ethernet connectivity

- Suitable for SIL2 (O2 only)

Applications

- Refineries

- Furnaces

- Boilers

- Safety applications

- Powerplants

- Chemical industries

- Petrochemical industries

- Steel industries

Customer Benefits

- Process optimization

- Simple installation, ease of use

- Low maintenance cost

- No consumables

- No sampling systems

- No regular calibrations needed

- Automatic span check available for certain gases

- SIL2 approved for O2

Iron and Steel Industry

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Boilers

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Coal Fired Power Stations

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Coke Ovens Gas

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

IECEx Certificate of Conformity

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CB Test Certificate

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.