Soft Drink & Juice

ProDetec is your pathway to monitoring key quality measuring points in your process. This results in higher product quality and less waste by giving you accurate and fast values that you can rely on to make the best decisions to keep you on top of your game. For example, to minimise product waste, you need to know that exact phase change between CIP and product.

We understand that the safety of your plant and people is paramount to you. For example, if part of your process involves the potential leakage of CO2. Discover how ProDetec is your partner in safety

If you can’t see your key measurement criteria below, send us a quick email with your specific needs.

Applications

- Turbidity

- Colour in Liquid

- Density

- Phase Change

- Dissolved O2 in Liquid/Gas

- Dissolved CO2 in Liquid

- BRIX

- Carbonation

- SIP

- CIP

- Water Softening

- Water Conditioning

- Reverse Osmosis

- Pasteurisation

- Membrane Water De Aeration

- Additive Dosing

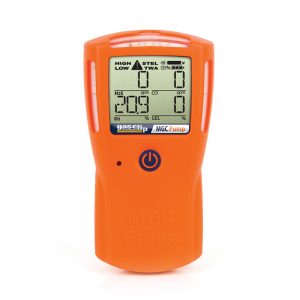

- Personal Gas Detectors

- Calibration and Test Gas

- Fixed Gas Detection

- Truck Unloading/Earthing

- Fire and Explosion Safety

- Environmental/Ambient Dust Monitoring

- Audio/Visual Alarms

- Emergency Shutdown

Measuring turbidity is important for ensuring the quality of the final product, but also for monitoring and controlling individual process steps in the beverage and food industries. With a reliably measured turbidity value obtained during liquid analysis, you can sustainably increase the efficiency of your process

Colour is an important parameter not only to ensure the quality of the final product, but also for monitoring and controlling individual process steps in the beverage and food industries.

Measuring density of a sample is an important quality parameter of both raw materials and finished products. Various techniques enable the density of solid, viscous and liquid materials to be accurately determined e.g. metals, plastics, chemicals, lubricants and food.

With the use of an in-line phase switch, phase transitions in liquids can be detected accurately with the aid of turbidity or colour. This reduces product loss and results in reduced water and energy consumption.

OXYTRANS is a very precise, optical oxygen sensor for measurement of O2 in deaerated water and soft drinks. Dissolved oxygen has adverse impact on flavour stability and shelf

The CARBOTEC series are very precise carbon dioxide sensors for measurement of CO2 in beer and beer-based mixed drinks. Dissolved CO2 has a major impact on the quality and taste of the product.

Brix is the measurement in percentage by weight of sucrose in pure water solution. This designation of Brix degrees is only valid for pure sucrose solutions. Pure sucrose is extracted from sugar-cane or sugar-beet.

The Carbonator is designed for continuous injection of carbon dioxide into soft drinks and mineral water. A precisely defined and constant CO2 content is an essential quality feature for carbonated beverages.

Where more stringent hygienic standards apply, sterilization-in-place (SIP) is done after CIP cleaning. SIP kills harmful microorganisms that may have survived CIP or in cases where Cleaning-in-Place is not performed.

The purpose of Cleaning-in-Place (CIP) is to remove product residues and microorganisms from all wetted surfaces inside tanks, pipework and filling machines. Centec provide CIP skids for cold and hot cleaning in beverage industry.

The ion exchange system IONTEC softens water used for soft drinks and mineral water or for steam generation. Water hardness causes scale deposits in piping and process systems

Raw water quality depends greatly on its source. Based on the raw water quality and the specifications for the purified water, Centec select the most appropriate technologies for each client. Usually, multi-stage regimes are necessary for water purification

The reverse osmosis system REVOTEC produces demineralized water that is perfectly suited for manufacturing of soft drinks and mineral water. Considering the quality of the raw water, the unit is designed individually for each specific application.

By flash pasteurization harmful microorganisms in soft drinks and mineral water are killed with the aim of improving microbiological stability and shelf life of the product. Flash pasteurization is a well-established and cost-effective process in beverage industry.

Dissolved oxygen has adverse impact on flavour stability and shelf life. The deaeration system DGS removes O2 from water that is used for the production of soft drinks and mineral water. The system is compact and easily expandable.

The additive dosing system ADoS is used for dosing of ingredients such as vitamins, flavours and colours directly into the main product stream. The compact skid provides a high degree of flexibility for the production of different products (brands).

ProDetec can offer our customers innovative portable gas detectors that offer greater reliability, improved productivity, and better cost-efficiency to protect your workers from potential gas hazards. These gas detectors can be readily calibrated and tested on site with the aid of Automated Calibration and Bump Testing Stations.

At ProDetec we can supply specialised gases and gas mixtures to meet various and specific requirements. We work with you to understand your application and analyse your consumption patterns. This way we can offer the correct cylinder size that maximises your efficiency while minimising costs.

ProDetec has access the the worlds best gas detectors for a wide range of industries. Whether the need is for a single application or multiple sites and areas, our durable gas monitoring solutions meet your unique industrial needs. We offer a broad range of gas detectors and controllers to satisfy international certification standards such as SIL (Safety Integrity Level), Marine and IECEx.

During truck unloading the product can get charged electrostatically. This way the truck itself will be charged up, too (if the product is charged negatively, the truck will have a positive load). As a truck has a relatively large electric capacity, this may lead to very powerful spark discharges.

Dust explosions can occur frequently in industrial processes where combustible material is transported/ pneumatically or mechanically conveyed, heated, filtered, spray dried, milled and stored

Measure the ambient dust concentration trends in a factories to manage explosion risk and improve worker safety.

Manual alarm call points are designed for the purpose of raising an alarm manually once verification of a fire or emergency condition exists, by operating the push button or break glass the alarm signal can be raised.