Timber Processing

The need to increase productivity has led to the development of new machinery with higher feeding speeds. These higher speeds automatically increase the risk for a fire or explosion due to for example friction. The demand for production safety and fire prevention in the woodworking industry has therefore increased. By tailoring a fire protection system using fast IR-radiation detection and flame detection in combination with effective water spray extinguishing and water mist suppression, Firefly aims to avoid costly fires and dust explosions in the woodworking industry.

Applications

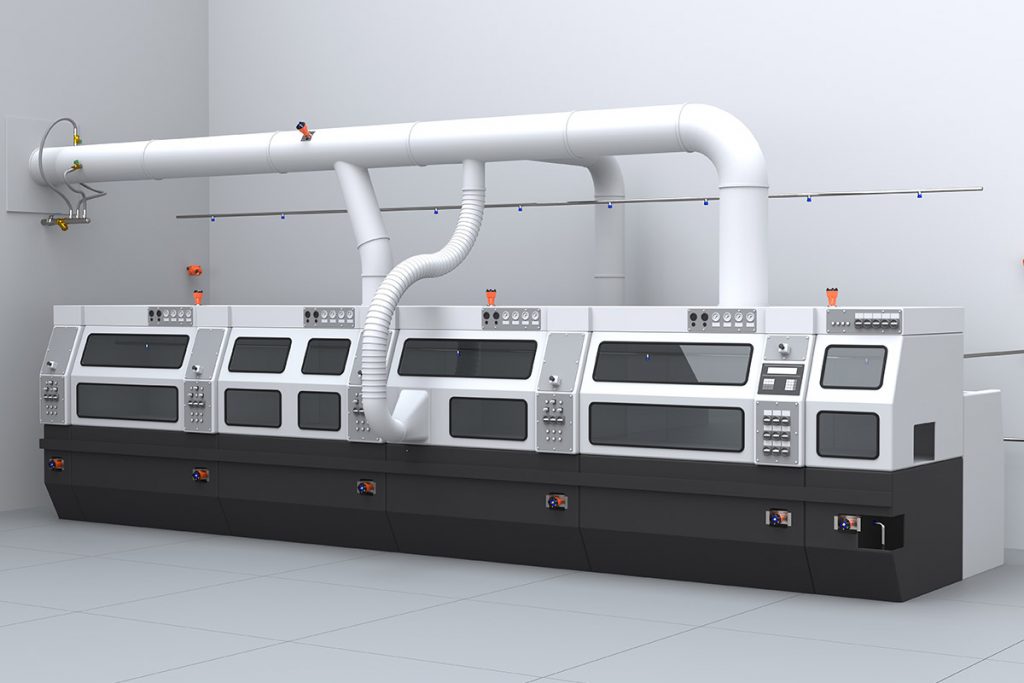

High Speed Planers

Modern High Speed Planers achieve speeds that were unthinkable a few years ago, this results in increased production which also elevates the risk of fire. Planing at high speeds leads to an increase in friction heat, making the process vulnerable to fire.

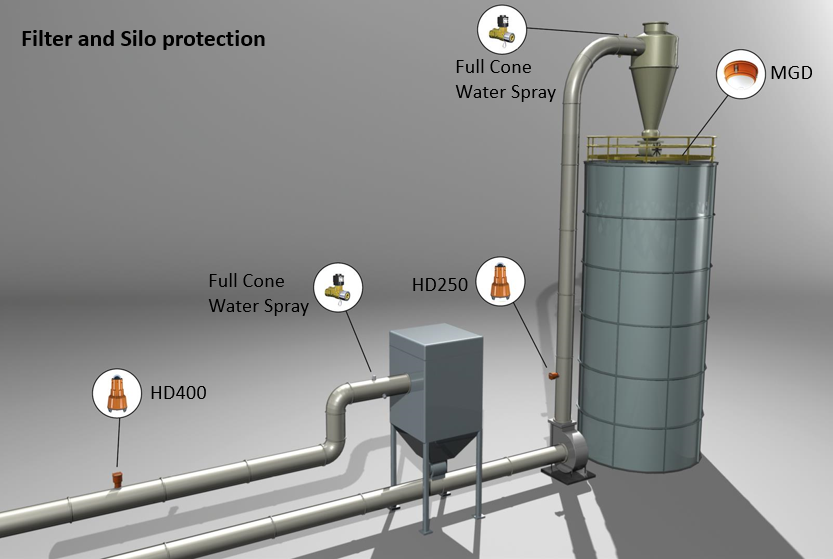

Why Filter and Silo Protection?

Filters and Silos are key components in the wood working process. A fire or dust explosion can have devastating consequences! Machinery can create ignition sources, there is a large risk that they will follow your production line into the filter.

Measure dust concentrations after filter units to quickly identify broken bags. Plant must be ensured that the air recycled back into the workshop does not have excess dust.

Continuous trend monitor that gives plant operators to see the performance of the filtration systems and ducts over a period of time. Perfect for installation after any filtration system or in common line channels leading into the emissions points of a plant.

Emissions monitors helps plant operators know exactly how much dust is passing through the stack or outlet duct of their plant.

Measure the ambient dust concentration trends in a factories to manage explosion risk and improve worker safety.

Dust explosions can occur frequently in industrial processes where combustible material is transported/ pneumatically or mechanically conveyed, heated, filtered, spray dried, milled and stored

ProDetec can offer our customers innovative portable gas detectors that offer greater reliability, improved productivity, and better cost-efficiency to protect your workers from potential gas hazards. These gas detectors can be readily calibrated and tested on site with the aid of Automated Calibration and Bump Testing Stations

At ProDetec we can supply specialised gases and gas mixtures to meet various and specific requirements. We work with you to understand your application and analyse your consumption patterns. This way we can offer the correct cylinder size that maximises your efficiency while minimising costs.