Description

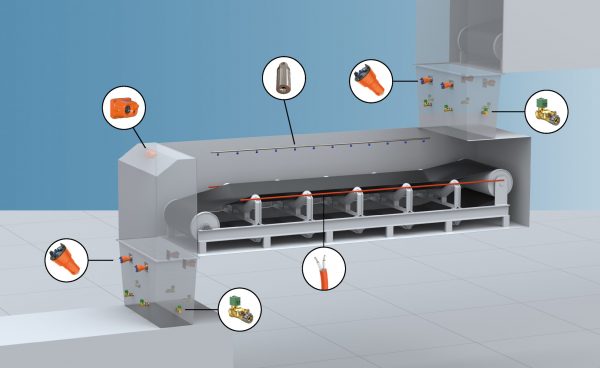

Technical Description – Conveyor Guard

Description

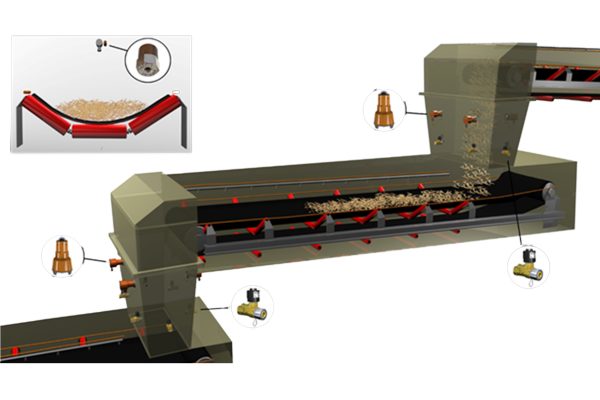

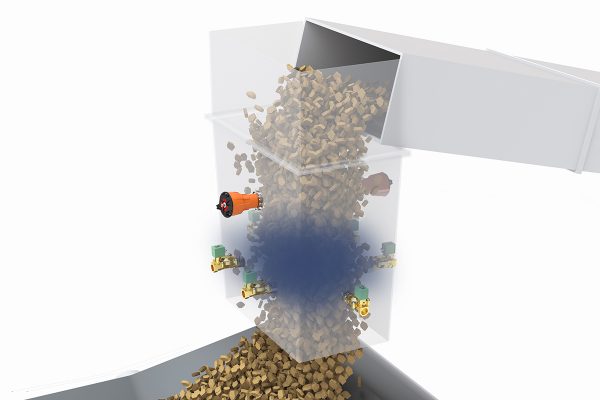

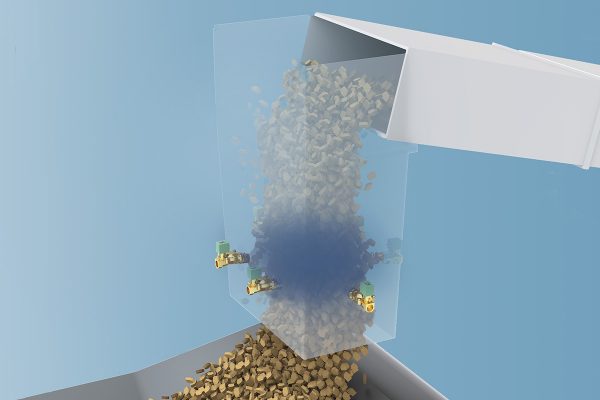

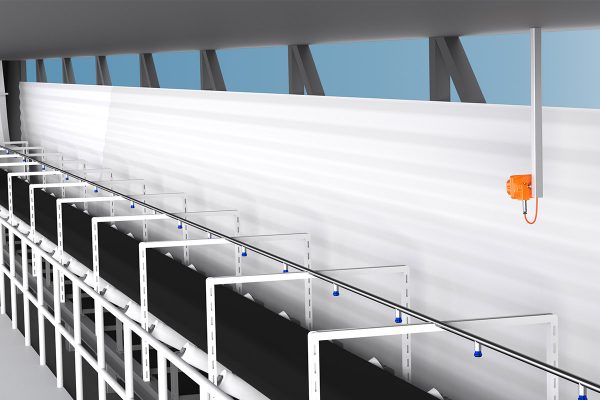

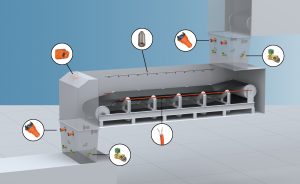

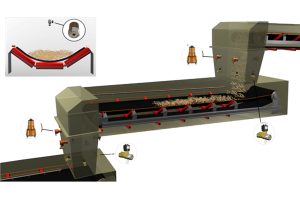

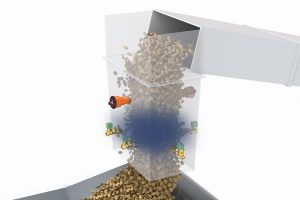

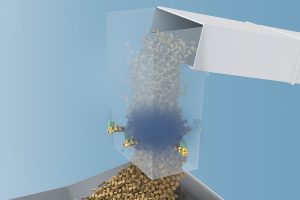

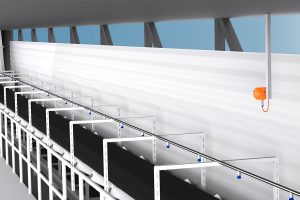

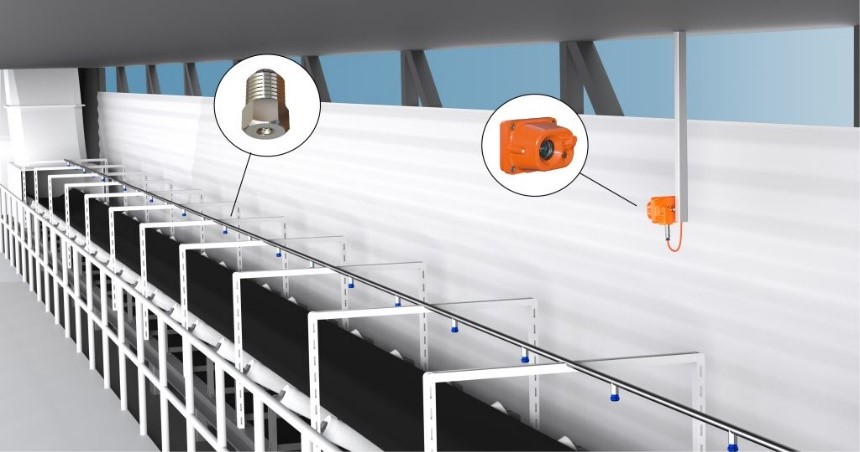

The ConveyorGuard™ solution consists of optical flame detection together with quick acting low-pressure water mist spray covering the entire length of the conveyor. The solution is customised to fit the actual conveyor design and can be used for different conveyor arrangements, such as belt conveyors, chain conveyors and screw conveyors, both open and enclosed types. Depending on e.g. the conveyor design, the customer’s enquiry and the risk analysis, the solution can be divided in zones and be complemented with linear temperature sensing cables (LTS) along the conveyor and spark detection- and extinguishing systems at the inlet- and outlet chutes.

There are not many certified water mist systems for conveyors, that have been fire tested and approved by an ISO certified and accredited test laboratory, so our ConveyorGuard™ system is incredibly unique in the market.

A Closer Look

ConveyorGuard for an open conveyor

ConveyorGuard for Enclosed Conveyor

High Risk! Big Consequences!

- Every year there are hundreds of fires in continuous presses throughout the world

- Most fires are small and only result in a production stop, but some have far worse consequences

- Only in South East Asia, many continuous presses have been destroyed by fire!

The single most valuable investment in a board plant with

- Long delivery time

- The press belt is extremely sensitive

- Even smaller fires can cause costly downtime. E.g. damaged steel belt or cables

Presses in board production

For many board mills throughout the world, a major fire in the press is a worst-case scenario. A press fire means long downtime at best. At worst, the consequences may be even more serious, with enormous capital loss as a result. The press is also a critical part of the board factory from a fire-safety point of view. In a press there is plenty of burnable fuel consisting of wooden dust, fibres and also thermal and hydraulic oil that pose a big threat in case of a leakage. Aged thermal oil has a reduced flash-/auto ignition point due to cracking processes that are taking place, especially when the oil is overheated. The press generates a lot of thermal energy that is continuously transferred to these layers and stacks of fuel, and after a certain exposing time the risk for a fire is urgent.

Furthermore, the continuous press is not an isolated unit from the rest of the plant, which means a fire can easily spread to or from the press through extraction ducts, building structures, cables, pits etc. This fact requires a protection system designed to protect not only the press, but also connected parts like pneumatic ducts or pump bays.

A basic press protection consists of two different parts, detection, and extinguishing. The detection must be quick and reliable and the extinguishing needs to be efficient without harming the electrical system or mechanical parts such as the steel belt.

When considering a protection system for the press, it is important to be aware of the economic consequences, the primary as well as the secondary, of downtime. Even small fires, causing downtime for a few hours, are expensive in the long run. The secondary effects, like bad will as a result of cancelled deliveries, are usually severe for a company and not covered by any insurance.

The Firefly solution

Firefly provides systems that minimize the risk of fires and explosions arising and spreading in a process. Installing such a system will increase safety as well as raising productivity.

To detect flames in working areas, a detector practically insensitive to other light sources than flames are used. To obtain a specific sensitivity for flames, UV and IR radiation is detected simultaneously and matched against the characteristic of a flame. Light sources like floodlights, welding arcs, sun light etc. will not be detected though the IR/UV characteristic differs from a flame.

A fast and accurate detection makes the extinguishing less extensive.

The extinguishing method normally used is the Firefly “Fine Particle Spray”. Droplets of a thoroughly tuned size are sprayed on the hot press and vaporize. The vapor then quenches the fire. This very efficient method results in an exceptionally smooth cooling of the press, which is important to avoid mechanical stress in the press. Also, the amount of water around the press after an extinguishing is reduced to a minimum.

Connecting parts are protected by any of the wide range of detectors and extinguishing methods supplied by Firefly. Firefly detectors covers a temperature from 150 ºC and upwards. This makes it possible to detect hot bodies (hot non-glowing bodies), which are the most common cause dust explosions according to the latest research.

Detection

Firefly has a wide range of detectors suitable for different applications.

Hot body detection is done by means of IR-sensors operating in the long-wave Infra-red spectral region, enabling detection of sparks, glowing particles, and black particles. All Firefly detectors are insensitive to daylight.

It is important to determine the minimum ignition temperature (MIT) of the processed material before choosing the detector. Note that a material can have different ignition temperature if it occurs in a dust cloud or in layers of dust. For example, wood dust has a MIT of about 470°C in a dust cloud (Filters cyclones etc), but only about 260°C in layers of dust (storage silos etc).

The OAD detector as shown above will detect flames. This is a two channel UV/IR flame detector which makes it highly insensitive to different type of external disturbance sources and can therefore be used in open areas, around machines etc, where sunlight etc is present. As a reference, the detector will detect flames from one by one-foot pan with kerosene at a distance of more than fifteen meters or a one decimetre gas flame in 4.5-5.0 meters.

If the temperature exceeds 50°C, the detectors must be equipped with CAR air cooling set.

Extinguishing / Diverting

After detecting the ignition source, it must be efficiently extinguished or diverted before it reaches the risk zone. Firefly can offer a variety of different extinguishing methods, depending on type of application and the availability of extinguishing medias.

Whatever method is chosen, the ”reaction time” for a Firefly preventive protection system, from detection to fully developed extinguishing zone, is always less than 3oo milliseconds including safety marginal. This means that the extinguishing zone must be located about 9 meters downstream in a pneumatic duct (based on 30meter/sec) or about 500 mm below the detectors in a fall chute.

Water mist

The water mist nozzles are to be installed around the machine or into the protected volume. The exact location will be determined by a site visit. The required water pressure is 7-9 bars and the water flow is only 10 litres per minute per nozzle.

Firefly PressGuard Advantages

- Quick reaction time

- Firefly PressGuard™ is the world’s quickest press protection system. Down to only 2 seconds from detection to developed extinguishing zone

- Efficient flame detection

- Firefly has a wide range of detectors to meet the requirements in different areas of the press

- Avoid false alarms

- Unique detection with UV/IR technology – NOT sensitive to photo flash, sunlight, etc.

- Highly efficient water mist extinguishing

- The small water droplets (only 120 μm) will quickly vaporise into steam. The steam effectively cools down the fire and quenches the flames

- Minimum water usage

- Smaller water droplets will heat up and evaporate more quickly resulting in better performance and more effective use of water

- Non-invasive extinguishing – minimises risk for damage

- Thanks to the small water droplets and low water volumes, Firefly PressGuard™ water mist extinguishing will minimise the effect on your press and its steel belt

- Risk Analysis and On-Site System Adaptation visit included

- The Firefly PressGuard™ system is always tailor-made after your needs

Data Sheet - ConveyorGuard

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Firefly Certificates & Approvals

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.