Description

Technical Description – Flash Pasto

Flash Pasteurization

By flash pasteurization harmful microorganisms in beer and beer-based mixed drinks are killed with the aim of improving microbiological stability and shelf life of the product. Flash pasteurization is a well-established and cost-effective process in brewery industry.

A Closer Look

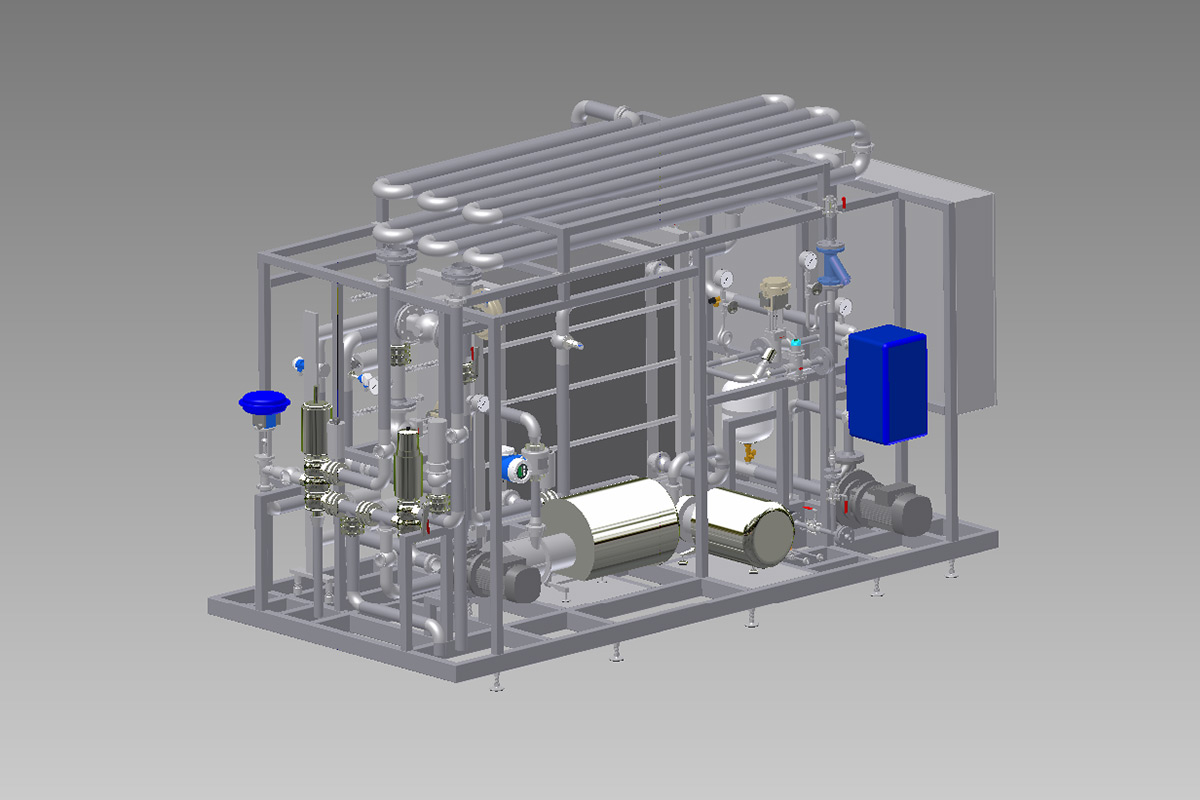

The flash pasteurization system is designed to pasteurize the product gently without adversely affecting its colour, taste or digestibility. For optimum results, pasteurization time, temperature and pressure must be individually adjusted. Optimum parameters depend on various factors, such as product, type of packaging and anticipated shelf life. Based on highly accurate process control, the unit guarantees constant pasteurization quality even at variable product flow directly in front of the filler. To increase the energy efficiency of the system, the product is warmed up to the pasteurization temperature in two steps. In the first step it is heated in a heat recovery section where it flows in counter current to the hot, already pasteurized product. In the second step it is gently brought to the pasteurization temperature by the heating medium, e. g. hot water, heated by steam. If the flash pasteurization system is installed directly in front of the filling machine, it can compensate for variations of product quantity picked up by the filler. CIP cleaning of the unit can take place as the same time as the main line or separately.

- Constant pasteurization quality by highly accurate PU control

- Buffer tank on demand for installation in front of the filler

- Customized modular design with a standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

The Specs at a Glance

| Capacity | 5 – 1.000 hl/h |

| Deactivation Temperature/Holding Time | depending on product/application |

| Heat Recovery Rate | 92 % (higher on request)

|

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Heating Medium | hot water, steam (primary source) |

| Cooling Medium | glycol, ice water, ammonia, brine |

| Options | different automation levels; remote maintenance access; buffer tank; cooling |