Description

Technical Description – ShredderGuard

Description

The shredding process is highly exposed to fire incidents. Foreign unwanted objects such as stones or metal pieces in combination with dust often start fires in waste shredder. Also paper shredders are commonly exposed to fires due to dust generated by the shredding process.

False alarms due to light is the most common problem with conventional spark detection systems using photocell detectors.

In a shredding line there are many areas where light can enter

- Openings into the process

- Doors or hatches

False detection will lead to unnecessary water injection and costly production stop

ShredderGuard Solution

Data Sheet - ShredderGuard

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

ShredderGuard - Lindner

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

ShredderGuard - Untha

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

ShredderGuard - Veco

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Application Note –Recycling Industry

- Handling and processing of used materials are increasing

- More people and increasing wealth – more products and packaging

- Recycling reduces the need for raw materials

- Waste to energy

- Material recovery facilities

- Cement plants

- Power plants

- Machinery suppliers

Materials

- Paper

- Plastic

- Wood

- Rubber

- Mix of different Wastes

- Combustible

- Often Dry

- Finely Divided

- Dust

Risks

- Several steps from receiving area to end of process chain – friction related problems

- Shredders

- Large amount of combustible materials and dust

- Large storage areas

- Complexity – difficult to manually extinguish fires

Often large facilities with several fire hazardous processing steps

- Receiving area

- Shredders

- Conveyors

- Screeners/separators

- Storages

- Balers

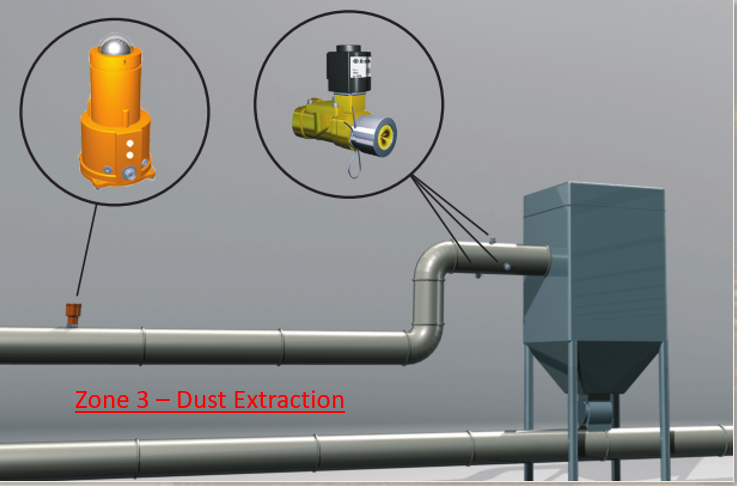

- Filters

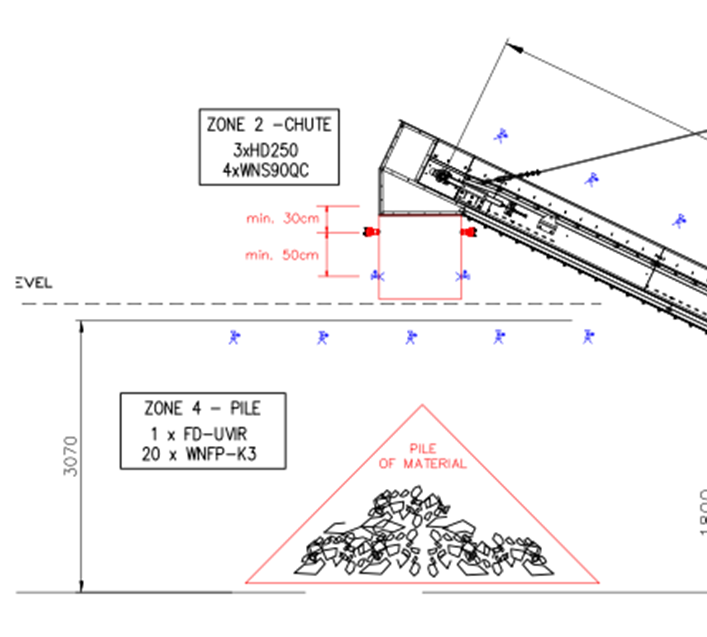

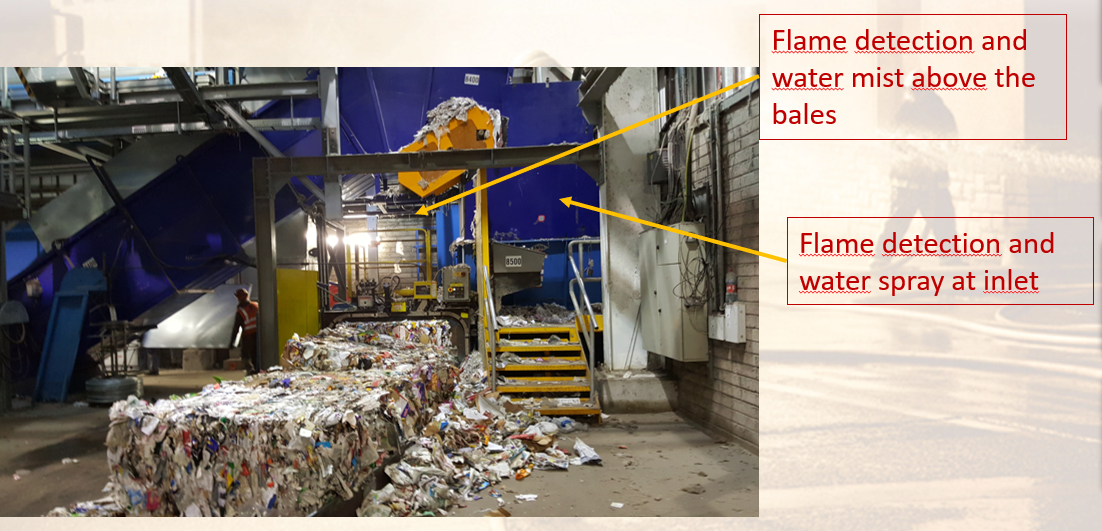

Receiving Area

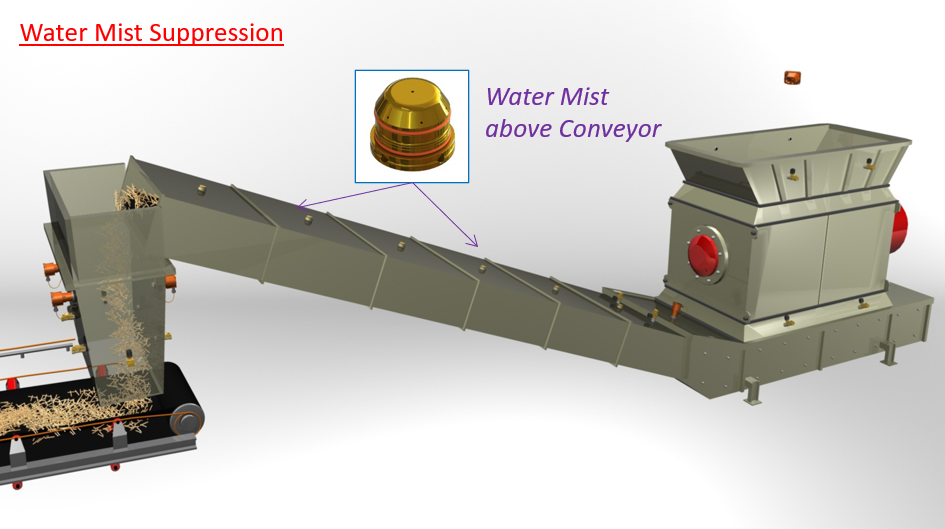

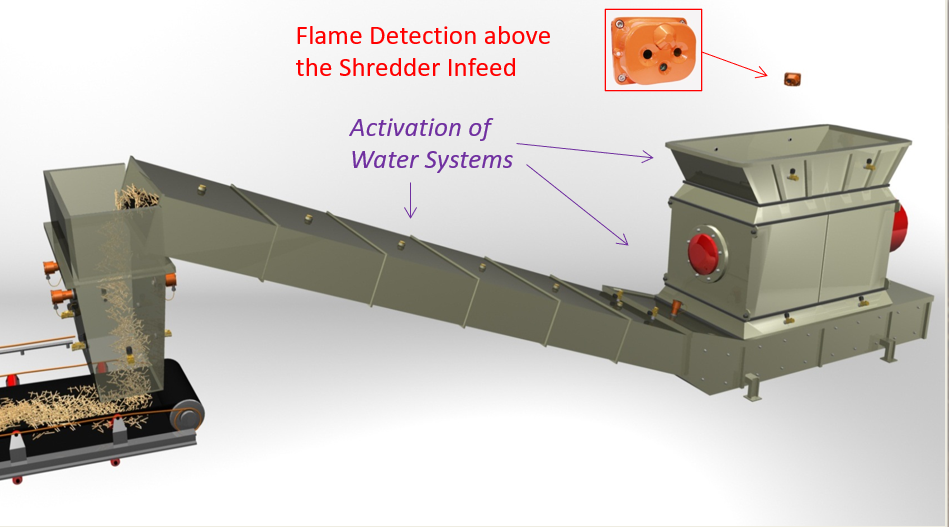

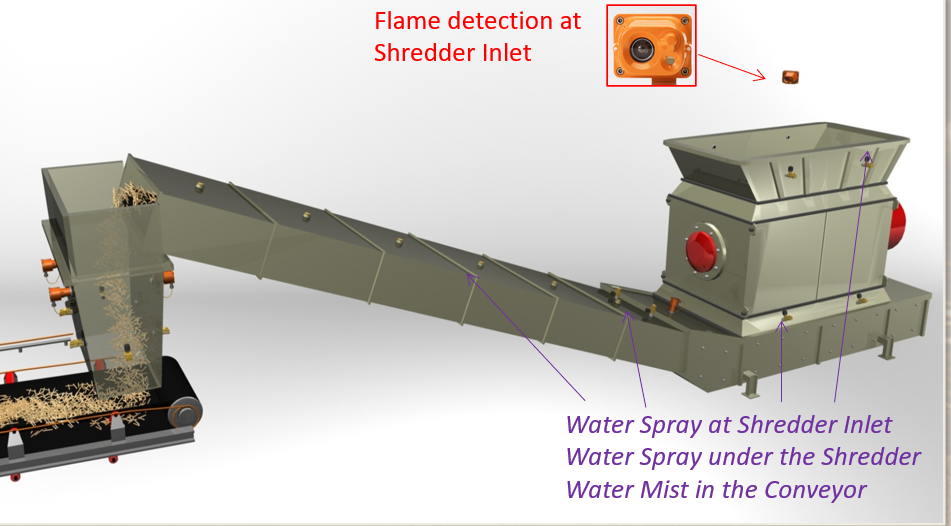

Flame Detectors and Water Mist

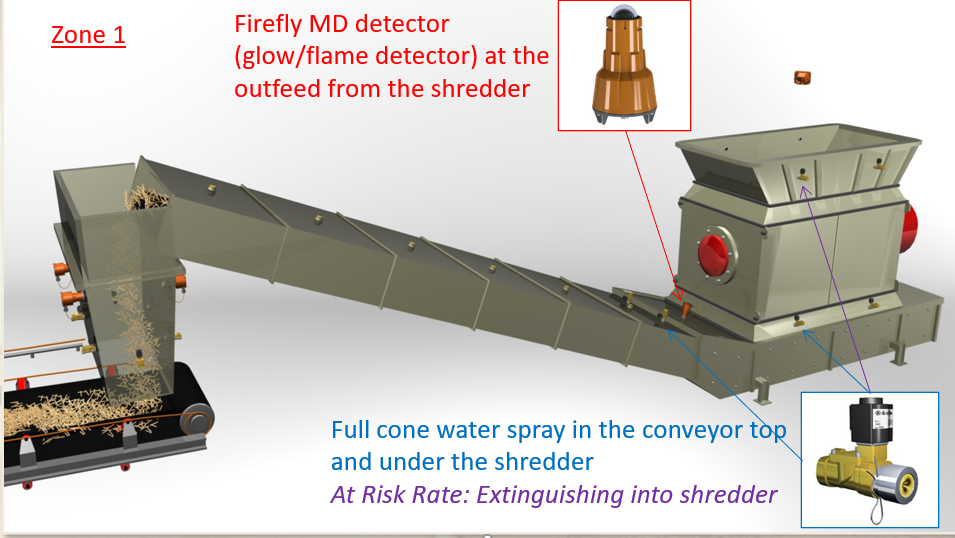

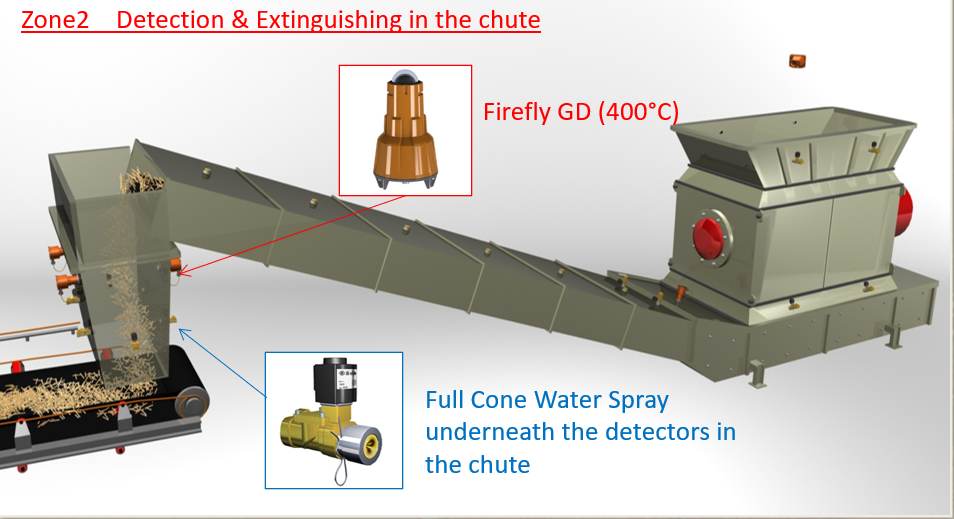

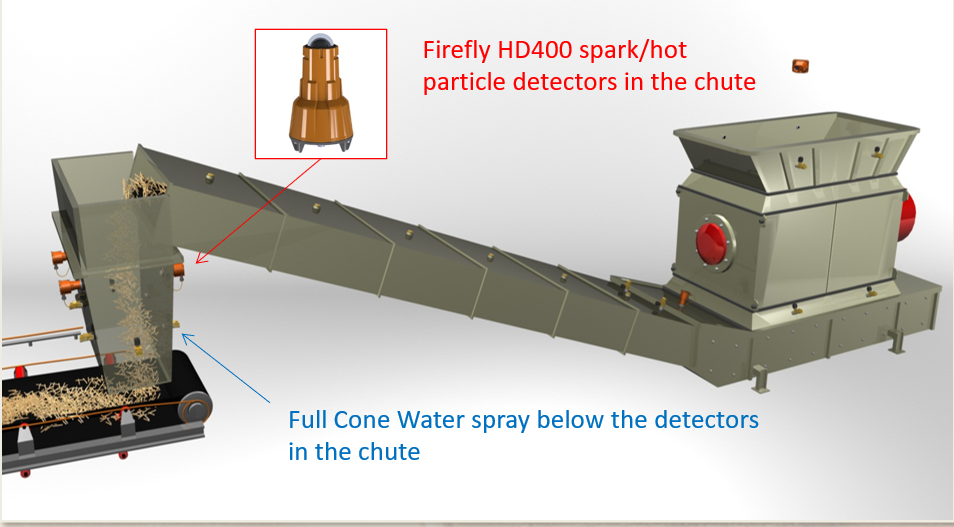

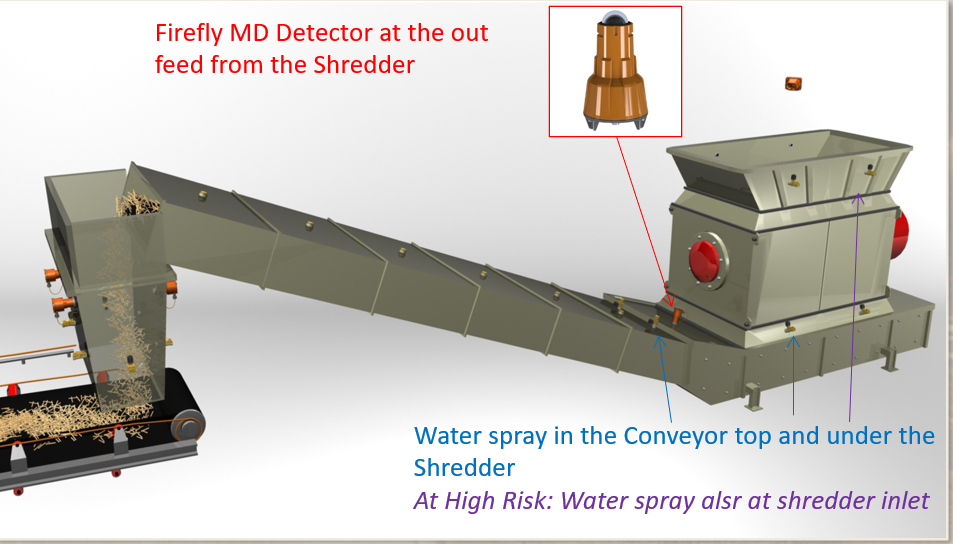

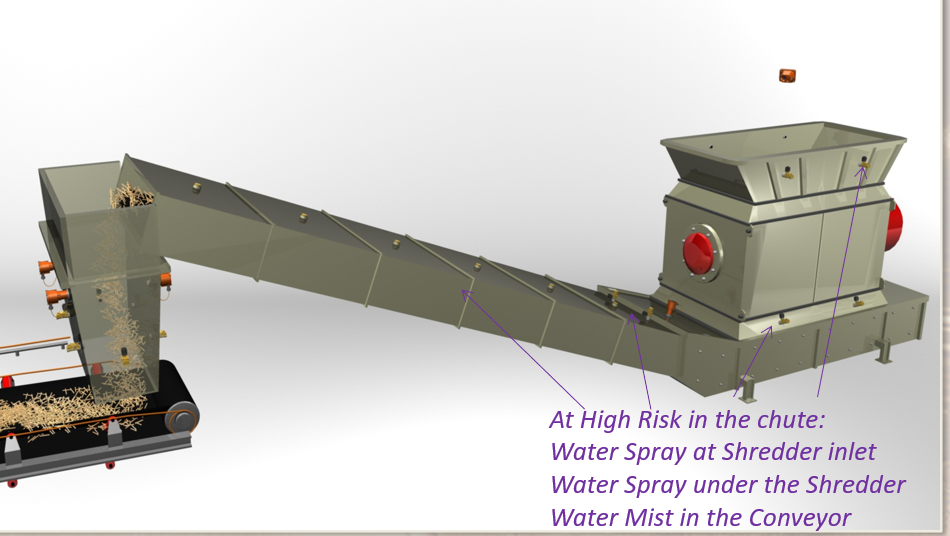

The ShredderGuard Solution

Shredders

- The shredding process is highly exposed to fire incidents

- Undesired items (stones, metal pieces, etc) and stripes

- Mechanical break-down

- Generates dust

- Very tough environment

- Requires damage resistant safety equipment

- Application with a lot of “disturbance sources”

Storage Area

Filter Protection

Baler Protection

Firefly Certificates & Approvals

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.