Description

Technical Description – Tissue Solutions

Principle of Firefly Quick Suppression System

- Complete systems designed for extremely quick detection and suppression of fires

- Can be used for spot-protection of any type of machine or high-risk area

- Ideal for many different applications within the Tissue Industry

- Over 700 systems supplied since 2000

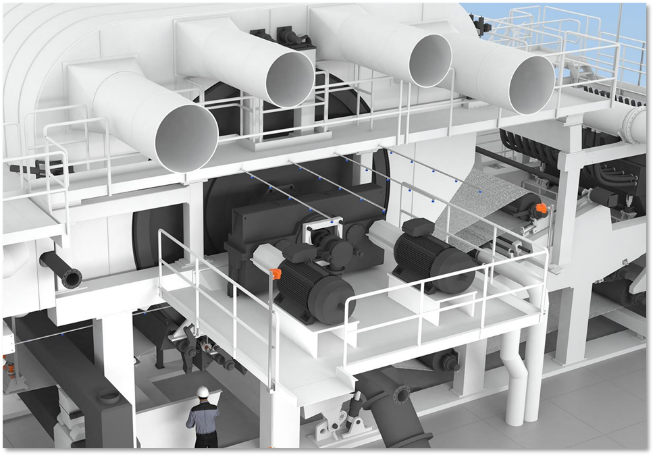

Firefly – Quick Suppression System Includes

Fast Response Flame Detectors

- High performance flame detectors

- Quick reaction time

- Many different type of detectors to suit each application

Quick Acting Water Mist

- Efficient suppression of flames

- Uses a small amount of water

- Water system designed for rapid response time

The Quick Suppression System can also be combined and Integrated with a Firefly Spark Detection System

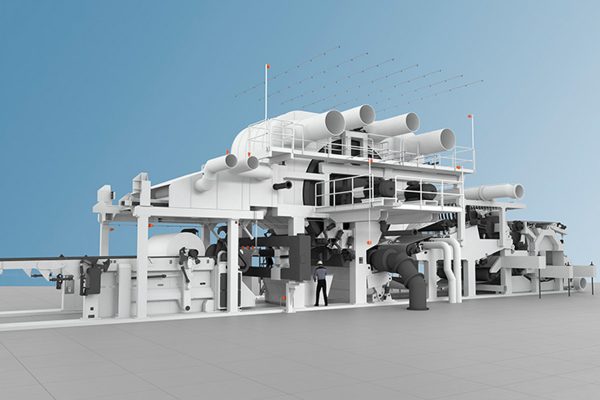

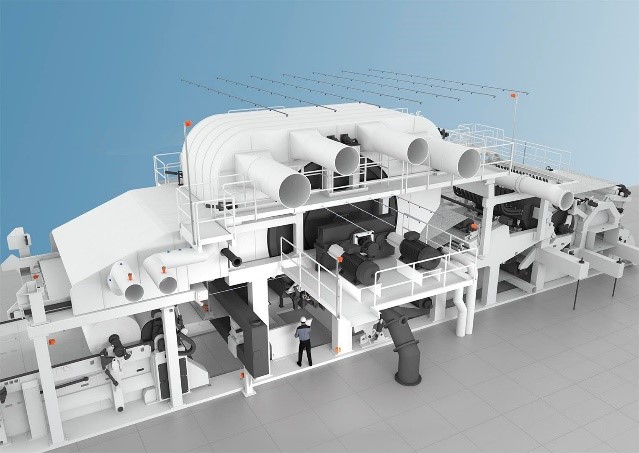

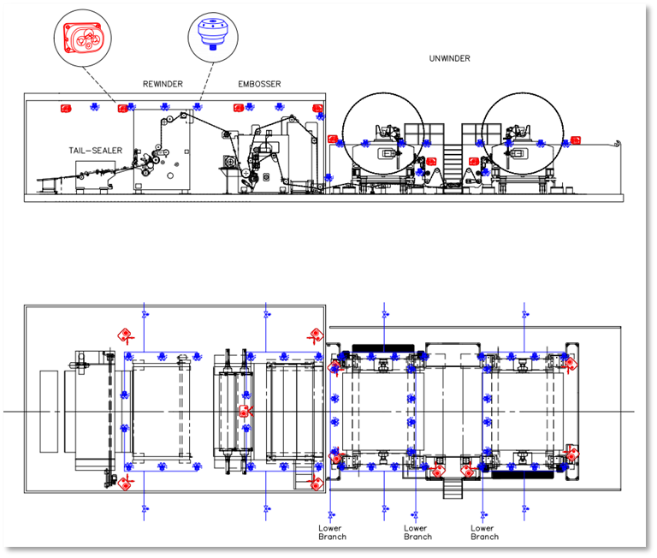

Solutions for the Tissue Machine

Top of Yankee Hood and Ducts

Problem

- Dust and material build-ups ignites by hot surfaces or overheated bearings/motors etc.

Detection

- Quick flame detection located on top or around the Yankee.

Suppression

- Water mist suppression at the top of the Yankee as well as at the backside of the Yankee

Yankee Dive Side

Problem

- Dust and material build-ups ignites by hot surfaces or overheated bearings/motors etc.

Detection

- Quick flame detection located on top or around the Yankee.

Suppression

- Water mist suppression at the top of the Yankee as well as at the backside of the Yankee

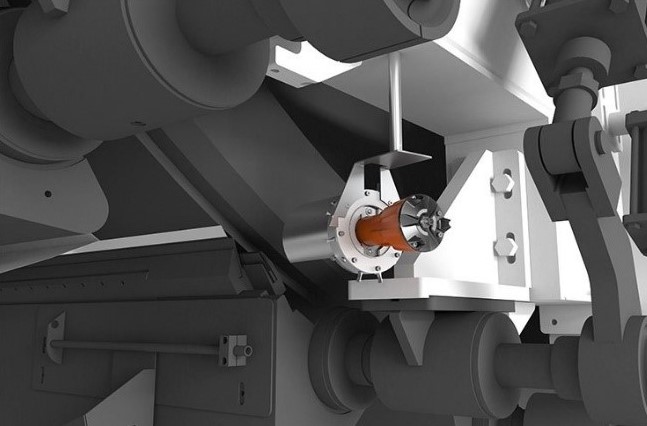

Firefly Spark Alert Yankee Cylinder

Problem

- Dust on bolts and ledges, etc at the side of the yankee cylinder can start to smoulder. If this happens, glows can randomly let off and being thrown into areas around the machine, starting fires.

Solution

- One or more Firefly GD-detectors are located at the drive side, around the yankee cylinder.

- Water mist nozzles are located around the yankee cylinder.

- If glows are detected, the water mist will be activated immediately.

Protection of Doctor Blades

Problem

- Dust accumulations around the doctor blade area can easily ignite by sparks or friction from the doctor blades.

- Due to the large accumulations of dust in this area a fire can quickly be spread further in the production hall

Detection

- Quick flame detection located at the sides of the machine, around the doctor blades

Suppression

- A Water mist suppression system is located at the sides of the doctor blades

Firefly WEBSCAN

Problem

- Sparks or hot spots in the tissue paper can be winded up into the jumbo roll. This can start a fire in the warehouse OR in the Rewinder operation.

Detection

- WD detectors are located to monitor the full width of the tissue paper. To detect hot particles or glowing embers in the tissue web.

Extinguishing

- Signal to operators – jumbo roll must be moved to uncritical area.

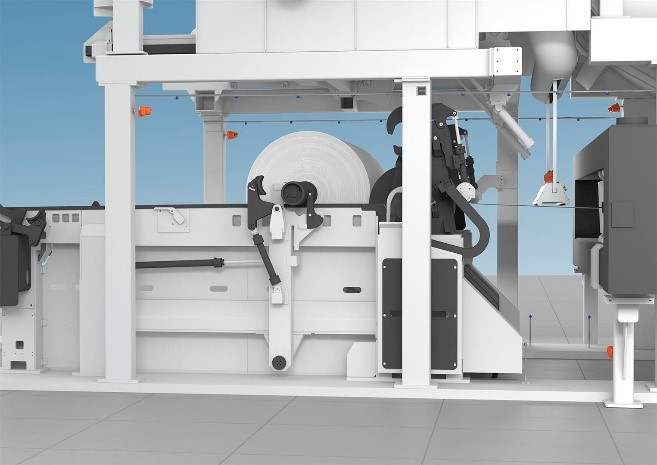

Reel Up

Problem

- Paper or paper stripes are often found in this area after changing into a new mother roll. This, in combination with the accumulation of dust creates large amounts of fuel for a fire. Ignition is often caused by friction heat from the bearings or friction caused by paper stripes winded around the shaft of the cylinders

Solution

- Quick acting flame detectors and water mist suppression system is located at the Reel-Up area

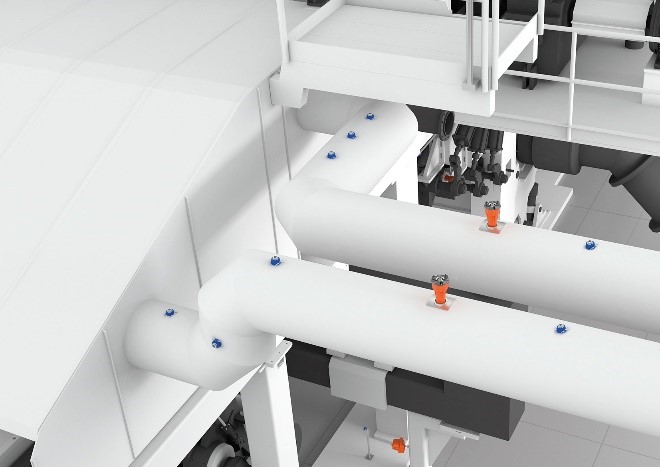

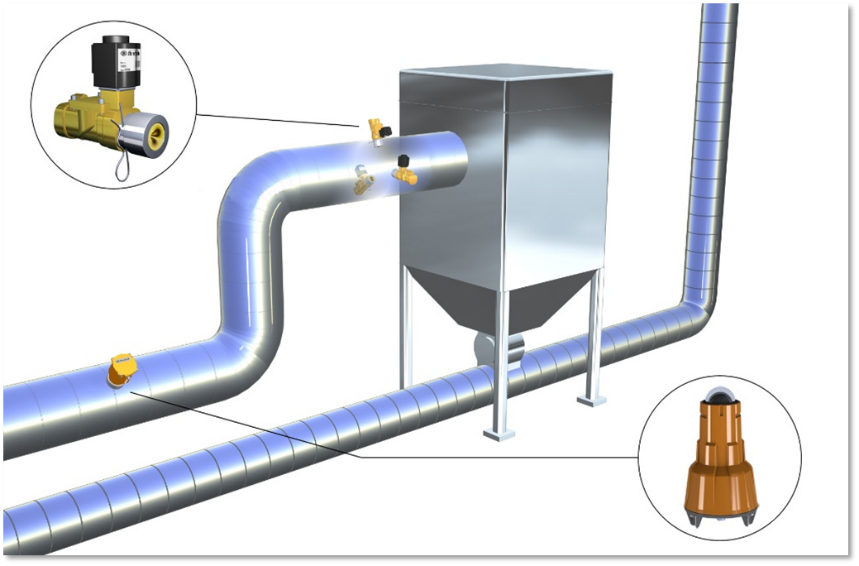

Dust Removal System

Problem

- Dust will often build-up and accumulate inside the suction boxes and inside the duct system.

If an ignition source enters the material can easily ignite and start a fire inside the dust removal system.

Detection

- Firefly Spark/ Hot particle detectors located into the duct work of the dust removal system.

Suppression

- Water spray nozzles into the duct work of the dust removal system

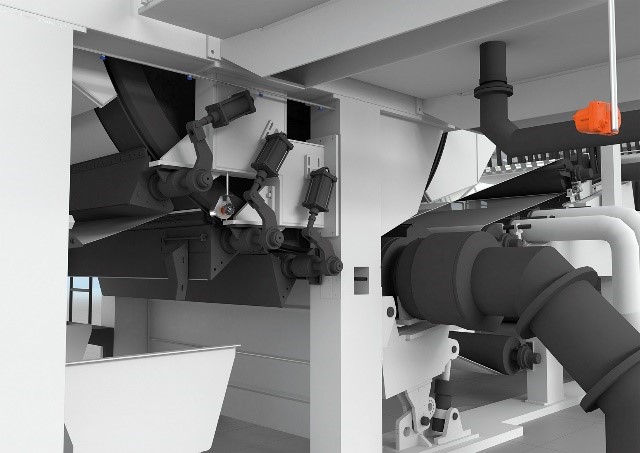

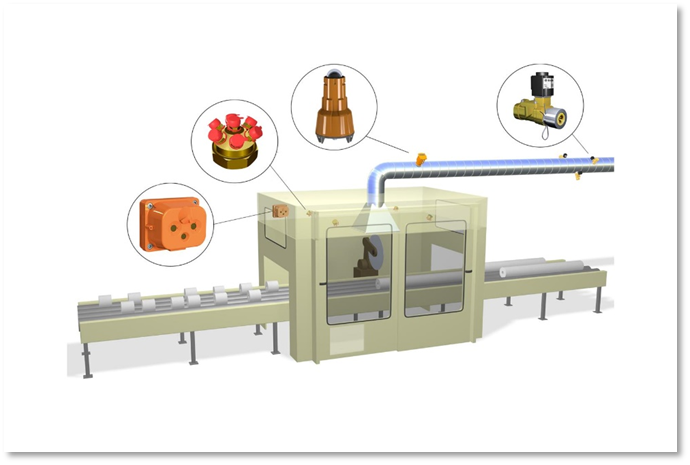

Tissue Converting

Problem

- The converting process normally generates a lot of dust, which can be ignited due to friction in bearings or friction by tissue stripes around shaft for cylinders

- If the machine is enclosed, even more dust is accumulated inside and also sprinkler in the production hall will not be able to reach

Solution

- Firefly Quick Suppression System around the converting machine with flame detection and water mist extinguishing

Log Saw Protection

Problem

- Sparks generated by the sharpening, due to bearing problem or mechanical breakdown can cause ignition of the dust in the log saw booth.

Detection

- Quick flame detection in the upper part of the booth. Sometimes also flame detection in the bottom part of the booth. Spark / hot body detector in the extraction duct

Extinguishing

- Water mist suppression inside the booth.

- Full cone water spray in the extraction duct

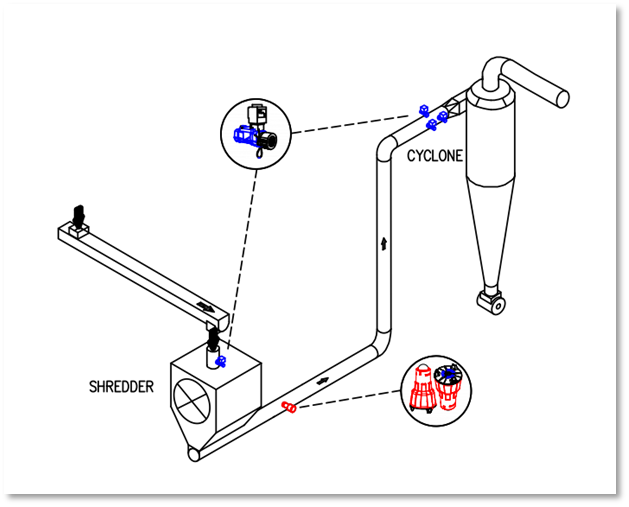

Paper Shredder Protection

Problem

- Ignition sources can be generated in the shredding process due to problem in the shredder causing friction or if metal or other pieces are fed into the shredder.

- The fire will most likely occur in the cyclone or filter where the shredded material is pneumatically conveyed.

Detection

- Firefly spark / hot particle detector in the duct (HD400)

Extinguishing

- Full cone water spray in the pneumatic transport duct and into the shredder

Protection of the Filter

Data Sheet - Tissue Solutions

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Data Sheet - Firefly Eximio

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Firefly Certificates & Approvals

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.