Description

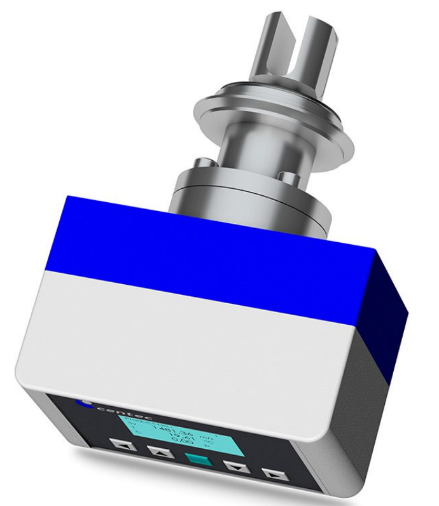

Technical Description – Brix Monitor

Accurate monitoring of inline sugar concentration

The Centec Brix Monitor provides highly accurate monitoring of inline sugar concentration. The °Brix value of sugar syrups, soft drinks and fruit juice is performed by using either density using the Rhotec analyser or sound velocity, using the Centec SonaTec.

When installed inline, the Brix Monitor provides virtually maintenance-free and a built-in operator interface.

A Closer Look

The Centec BRIX MONITOR is based on either the RHOTEC (density measurement) or SONATEC (sound velocity measurement). We can guide you in the selection of the best instrument for your application.

For density measurement the liquid flows through a thin U-shaped tube inside the sensor. Using electromagnets, the tube is excited to oscillate at the resonant frequency. At the same time, an integrated reference oscillator measures the oscillation characteristics. Even the smallest changes in fluid density have an impact on the detected signal and are identified with highest precision. The instrument is designed for applications requiring maximum sensitivity and highest accuracy. It is easy to operate and maintenance-free.

For sound velocity measurement a sound pulse is created by a piezo-element in a sonic transmitter. It moves perpendicular to the product flow towards a sonic receiver where it is detected. Since the distance between transmitter and receiver is known, the sound velocity can easily be calculated by measuring the travel time of the sonic signal. As a specific property of each liquid, the correlation between concentration and density resp. sound velocity can be described by a mathematical polynomial.

With decades of experience and our own laboratory facilities, Centec has developed the polynomials for a large number of products. Any temperature drifts of the measured signal are automatically compensated for by an internal Pt1000 sensor.

The Specs at a Glance

| Measuring Range | 0 – 80 °Brix |

| Accuracy RHOTEC | ± 0.03 °Brix |

| Accuracy SONATEC | ± 0.07 °Brix |

| Measuring Temperature Range | -5 to 80 °C |

| Response Time | ≤ 1 s |

| Pressure of Operation | max. 16 bar |

| Temperature of Operation | – 25°C to 125 °C |

| Temperature Sensor | Pt1000 |

| Material | 1.4404/1.4435/AISI 316L; Hastelloy; Tantalum; others on request |

| Process Connections | Varivent DN40 – DN150 |

| Inputs | 6 x digital (24 VDC) |

| Outputs | 2 x (4 to 20 mA) and 3 x digital (24 VDC) |

| Profibus DP | Optional |

| Power Supply | 24 VDC |

Brix, Plato and ICUMSA

Degrees Brix (symbol °Bx) is the sugar content of an aqueous solution. One degree Brix is 1 gram of sucrose in 100 grams of solution and represents the strength of the solution as percentage by mass.

Comparable scales for indicating sucrose content are the degree Plato (°P), which is widely used by the brewing industry.

A sucrose solution with an apparent specific gravity (20°/20 °C) of 1.040 would be 9.99325 °Bx or 9.99359 °P . The representative sugar body, the International Commission for Uniform Methods of Sugar Analysis (ICUMSA), which favors the use of mass fraction, would report the solution strength as 9.99249%. Because the differences between the systems are of little practical significance (the differences are less than the precision of most common instruments) and wide historical use of the Brix unit, modern instruments calculate mass fraction using ICUMSA official formulas but report the result as °Bx.