Description

Why FireFly – Water Extinguishing

PowerImpact extinguishing™

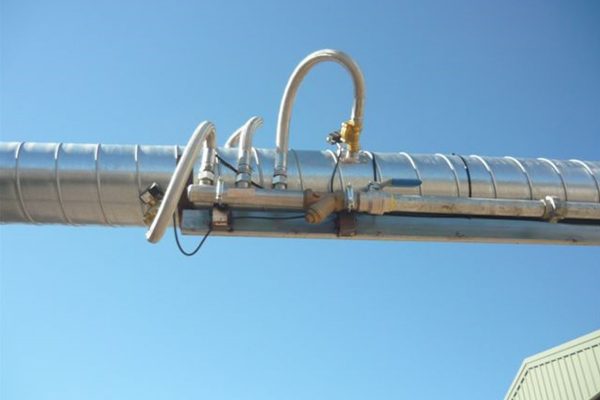

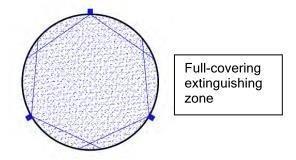

Firefly provides high-speed and powerful full-cone extinguishing with a unique nozzle design and placement from different directions aimed to penetrate and cover the entire material flow inside a pneumatic conveying system or chute.

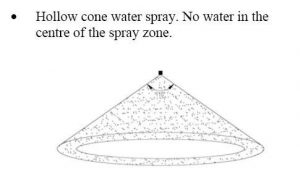

Conventional extinguishing systems use hollow-cone spray nozzles with relatively small water droplets, often installed only from one direction. Consequently, conventional extinguishing provides less ability to penetrate the entire material flow and can leave uncovered areas inside a pneumatic conveying system or chute.

Water Extinguishing in Ducts

| Fire Extinguishing in Ducts | Standard Spark Detection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water Extinguishing for Pressers and Planers

| Firefly – Water Mist | Other Manufacturing |

|

|

|

Water Extinguishing

Process industries generally handle large material flows; from hundreds of kilos up to hundreds of tons per hour. High flows of compact material demand a powerful extinguishing which is able to fully penetrate these flows.

Water is the most common method of extinguishing. However, dangerous particles can also be eliminated by means of mechanical diversion, isolation, steam or gas in applications where water is not suitable for use in the process.

If you use water extinguishing to protect your process from fires and dust explosions:

- Require extinguishing from different directions in order to secure full coverage of the entire cross-section of a duct or chute.

- Extinguishing needs to be powerful enough to penetrate also large and compact material flows.

- Extinguishing needs to react within milliseconds after detection.

Application Note – Fast Water Mist Systems

How does Water Mist work?

The small water droplets will evaporate into steam

- COOLING – when turning into vapor, the water mist absorbs more heat from the fire than any other extinguishing agent (>2 MJ/kg)

- INERTING – when evaporating, the water particles expand by 1700 times, thereby displacing the oxygen

- HEAT ABSORBTION – the water mist will ”block” the heat transfer from the fire

Critical water droplet size

- Smaller water droplets have a larger specific surface area and a quicker evaporation – More efficient extinguishing!

- This means that smaller water droplets have a more efficient usage of the water volume – Less water can be used!

Consider

- Too small water droplets have less momentum and could follow the thermic airflow from the press

- Too large water droplets require larger water volumes to achieve the same extinguishing effect and there is a risk for rapid cooling of the press construction and steel belt

|

1 Litre of Water |

||

| Droplet Size (mm) | No. of Droplets | Surface Area (m2) |

| 1 | 1 900 | 0.6 |

| 0.1 | 1 900 00 | 6 |

| 0.01 | 1 900 000 000 | 60 |

Water Extinguishing

Full cone water spray

Used in pneumatic ducts of fall chute, to penetrate the airflow or material flow

Full cone water spray Water nozzles WNSXXQC:

Note that nozzles WNS means wide spray angle (110°)

This is the normal nozzle we use

WNS50QC: 50 lit/min (used when less water is required)

WNS75QC: 75 lit/min (Standard nozzle for dust extraction ducts)

WNS90QC: 90 lit/min (Standard nozzle for material transport ducts OR fall chutes)

WNS120QC: 120 lit/min (Used for black powder applications)

Full cone water spray Water nozzles WNXXQC:

Note that nozzles WN have a narrower spray angle (60°). The spray distance from these nozzles will be longer. This can be used in larger ducts of very dense material flow where we need to penetrate the material flow.

Note that we often need to compensate with more nozzles due to the smaller spray angle

Available nozzles: WN50QC, WN75QC, WN90QC and WN120QC

Firefly Certificates & Approvals

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Other Extinguishing Methods

Firefly offers a wide variety of methods for extinguishing, isolation or diversion of ignition sources for processes where the use of water is not suitable.

Firefly’s ultra-fast isolation and diverter valves are known for their high quality and superb functionality and are available in many types and sizes. CO2 gas is often used in combination with isolation valves to inert the isolated process volume.

Also other extinguishing methods such as inert gas, foam, steam or other chemical agents can be included in Firefly’s system solutions.