Description

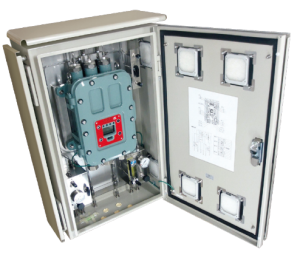

Technical Description – OHC800 Explosion Proof Calorimeter

World’s first RIKEN OPT-SONIC method

Evaluating the calorific value of fuel gas by measuring the sound speed and the light speed passing through the fuel gas.

This calorimeter is an explosion-proof calorimeter in a flame-proof enclosure designed for continuous, fast-response measurement of the “Calorific value,” “Density,” and “WOBBE index” of various fuel gases such as natural gas, coke oven gas, blast furnace gas, converter gas, biomass gas, and biogas.

The types of fuel gases that can be measured depend on the specifications. For information on the types of gases that can be measured by the product, check the “Measuring gas specification sheet” provided with it.

Measurement data can be updated every 0.25 seconds, a feature which is not possible with gas chromatography. Robust design for all measurement environments eliminates the risk of measurement outages.

The calorimeter measures the speeds of “light” and “sound” that travel through the measuring gas by using an “optical sensor” and a “sonic sensor” and applying the Opt-Sonic calculation processing* to the measuring result. This enables the high-accuracy measurement of “Calorific value” and “Density” of fuel gases containing interference gases such as nitrogen and carbon dioxide.

A Closer look

- The calorimeter can be used with minimum equipment even under constraint conditions with its high environmental resistance.

- The calorimeter, having an advanced self-monitoring/diagnostic function compliant with NAMUR NE107 (self-monitoring/diagnostic of field devices), offers functions for performing real-time status monitoring for devices and informing abnormal statuses and maintenance requests with LCD display and contact output.

- The calorimeter has a log data auto-save function that records the history of “operation statuses” and “self-diagnostic results” for a year or longer. Furthermore, another function provides outputting the log data via IrDA communication, which can be used for high-quality maintenance/follow-up services. (Optional services)

- The calorimeter forms a “complete stand-alone unit structure” that consists of standardized units. Even if any malfunction occurs, quick repair and recovery can be achieved just by replacing a faulty unit on site.

The Specs at a Glance

| Model | OHC-800 |

| Measuring Principle | Opt-Sonic method through measurement of light speed and sound speed |

| Measuring gas (*1) | CH4 basis Paraffinic Hydrocarbon gases as represented by Natural Gas (*2)

|

| Measuring targets | Calorific value (Density / WOBBE index selectable) |

| Measuring range (*3) | Calorific value : 25.00 – 50.00 MJ/m3 (Gross, 0 degree C, 101.325kPa converted) Density : 0.500~1.500 MJ/m3 (Specific gravity converted)

|

| Measuring method

|

Constant-flow-rate gas introduction using external sampling devices |

| Display | Full-dot LCD (with backlight), 3 color LED lamp |

| Full-dot LCD (with backlight), 3 color LED lamp

|

4-20 mA DC (isolated, source current type) maximum load resistance of 300 Ω / RS-485 communication |

| Failure alarm | Low flow, Sensor unit abnormality, Low light amount |

| Failure alarm display | Lamp (red) / Content indication on LCD |

| Failure alarm contact (*4) | No-voltage contact 1a or 1b De-energize (Energize when alarming) or Energize (De-energize when alarming) Contact capacity of 2 A, 30 VDC (resistance load)

|

| Self-diagnostic function | FUNCTION CHECK (warm-up or maintenance mode), MAINTENANCE REQUIRED, OUT OF SPECIFICATION |

| Self-diagnostic display | FUNCTION CHECK, OUT OF SPECIFICATION : Lamp (orange) / Content indication on LCD MAINTENANCE REQUIRED : Lamp (green) / Content indication on LCD |

| Self-diagnostic contact (*4) |

FUNCTION CHECK, OUT OF SPECIFICATION : No-voltage contact 1a or 1b De-energize (Energize when alarming) or Energize (De-energize when alarming) Contact capacity of 2 A, 30 VDC (resistance load) MAINTENANCE REQUIRED : SSR contact, contact capacity of 20 W, 240 VAC (resistance load)

|

| Power supply | 100 – 240 VAC ±10%, 50/60 Hz, max. 18 VA or 24 VDC ±10%, max. 5 W (The setting can be changed to either the AC or DC) |

| Ingress Protection level | Equivalent to IP66 and IP67 |

| Operation temperature | -20 to+60 ℃ (-4 to +140 ℉)(ATEX / IECEx)/ -20 to+57 ℃ (-4 to +134.6 ℉)(Japan EX) |

| Operation humidity | 95%RH or less (no condensing) |

| Outer dimensions / Weight | Approx. 286 (W) x 453 (H) x 150 (D) mm / Approx. 23 kg (50.7 lbs) |

| Explosion-proof structure | Flame-proof enclosures (Explosion-proof class: ExdⅡB+H2 T4 <Japan EX>/Ⅱ2GExdⅡB+H2T4 <ATEX/IECEx>) |