Description

Technical Description – RSV Fast Shutting Gate Valve

Based on the Flash explosion suppression system and operating in a similar manner, Flash chemical barriers are capable of detection an explosion in an early stage by means of pressure or flame detectors.

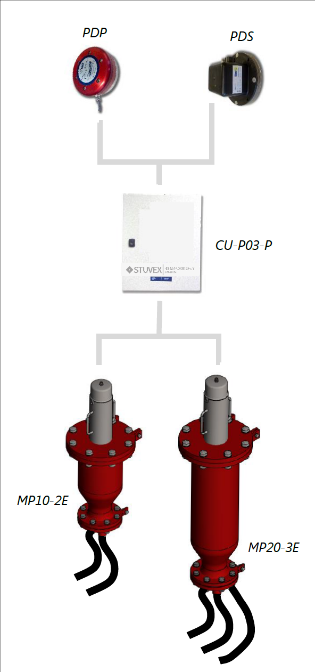

The Flash chemical barrier is modular in design and consists of three major building blocks:

Explosion detector(s), Control Unit, Gas Generator, and suppressor bottle.

A Closer Look

Main features

- ATEX certified chemical barrier

- Food compliant sodium bicarbonate suppressant powder

- Not subject to PED (Pressure Equipment Device) requirements

- Up to 4 exits per bottle

- Easy mounting onto existing process equipment

- Guideline: EN14373:2005

- Easy to operate and maintain

Explosion suppression system: three components

The FLASH explosion suppression system is a flexible, modular system consisting of:

- Explosion detectors triggered by static pressure, an increase in pressure, optical monitoring (UV, IR, UV/IR, …) or a combination of all of these

- A multifunctional modular control unit

- Ultra-fast powder extinguishers in different sizes and with various types of connection flanges depending on the application.

- This modular design makes it possible to assemble the optimal configuration, both technical and commercial, for each application.

The Specs at a Glance

Extremely fast explosion suppression

The detector continuously monitors the volume to be protected. In the case of a pressure increase or optical detection (depending on the system configuration and settings), the detector will send a signal to the control unit, which in turn will trigger the gas generators of the extinguishing agent bottles.

Then, within a few milliseconds, the huge amount of gas necessary to inject the extinguishing powder into the installation is produced. The powder kit, the extinguishing agent bottle and the gas generator itself are completely pressure free under normal working conditions. The injection of the extinguishing powder extinguishes the flame front. In addition, there is always enough extinguishing powder provided to make the entire volume inert so that no secondary explosion can occur.

For this reason, the process (and certainly the blowers) must be stopped immediately after Flash explosion suppression system is triggered, in order not to exhaust the extinguishing powder. If this cannot be guaranteed, cut off valves must be installed or supporting measures (such as steam injection) must be taken.

Process Introduction

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Dryer Atomising Tower

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Fluid Bed Dryer

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Elevators

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Silo

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Filter

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Explosion Suppression

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.