Description

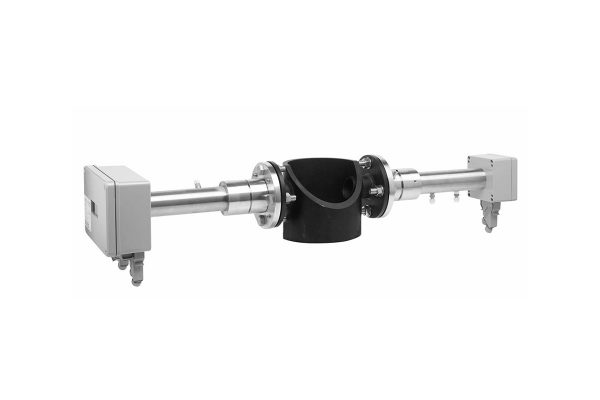

Technical Description – LaserGas™ II Compact

Features

- Fast response time

- Wide variety of gases and applications

- Compact design

Gases

- CH4

- CO %

- CO2 %

- CO ppm

- CO2 ppm

- H2O %

- H2O ppm

- H2S

- HCl

- HCl in VCM

- HCN

- HF

- N2O %

- N2O ppm

- NH3

- NO

- NO2

- O2

- C2H2

- C2H4

LIST OPP: NH3+H2O, HCl+H2O, HCl + CH4, HCN + NH3, HF + H2O, CO+CO2, CO+H2O, CO+CH4, H2S + CO2, O2+temp.

A Closer Look

- Response time down to 1 second

- No gas sampling: in-situ measurement

- No interference from background gases

- No moving parts, no consumables

- ATEX and CSA certified

- Can measure through very thin nozzles <10 mm diameter

- Optimised for very short distance measurements across pipes and along short cells

- Compact design

- No zero drift

- Stable calibration

Applications

- Chemical industry

- Petrochemical industry

- Metal industry

- Power plants

- Waste incinerators

- Cement industry

- Automotive industry

- Scrubber technology

- Glass industry

- PVC production

- Pulp and paper

- …and more

Customer Benefits

- In-situ monitoring

- Exceptionally reliable real time analyser

- Low maintenance cost

- Reduce emission to the environment

- Easy to install and operate

- Reduce daily operation costs

- Optimise process

- Well proven measurement technique

- Low purge flow

- Tailor made to your process

Fluid Catalytic Cracker (FCC)

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Coal Fired Power Stations

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cement Industry

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

CB Test Certificate

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.