Description

Technical Description – S100 Series Dust Monitor – Broken Bag Detector

Inductive Electrification

Sintrol dust monitors are based on a unique Inductive Electrification technology. The measurement is based on particles interacting with an isolated probe mounted into the duct or stack. When moving particles pass nearby or hit the probe a signal is induced. This signal is then processed through a series of Sintrol’s advanced algorithms to filter out the noise and provide the most accurate dust measurement output.

Classic triboelectric technology is based on the DC signal, which is caused by particles making contact with the sensor to transfer charges. Compared to DC based measurements, the Inductive Electrification technology is more sensitive and minimises the influence of sensor contamination, temperature drift and velocity changes. By using the Inductive Electrification technology, it is possible to reach dust concentration measurement thresholds as low as 0.01 mg/m3

A Closer Look

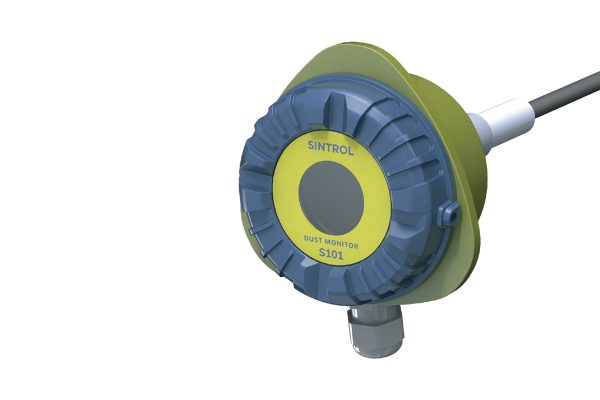

Dust Monitor for broken bag detection

The S101 is a basic cost-effective dust monitor to give indication of changes in dust levels from gas flow. This robust and sensitive monitor can be used in duct sizes with a diameter of less than 1 metre. The S101 is a real-time continuous dust monitor and will monitor for leaking or broken filters. The key features of the S101 are onboard red/yellow/green light to indicate dust levels, 2 solid state alarm relays and MODBUS RTU communication.

Auto Setup function makes commissioning easy and quick, and the two alarm signals enable easy connectivity.

The Specs at a Glance

| Enclosure: | Aluminium |

| Probe length: | 250 mm (9.84 in), can be shortened by the user |

| Probe material: | Stainless steel (316L) |

| Insulation material: | Polyether ether ketone (PEEK) |

| Output signal: | 2 × Independent solid-state relays |

| Communication protocol: | Modbus RTU or Sintrol network |

| Max. temperature: | 250 °C (482 °F) |

| Max. pressure: | 200 kPa (29 psi) |

| Flow speed: | Min. 3 m/s (9.84 ft/s), max. tested 40 m/s (131.23 ft/s) |

Bag Filter Management in Wood Dust Industry

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Process Monitoring in Pharmaceutical Industry

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

RF Network Paper Machinery Industry

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Steel Manufacturing Industry Process

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Animal Food Manufacturing

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Continuous dust monitoring to assure Flour Mill hygiene

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

EN12779 for Wood Industry

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Cement Manufacturing Process

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sintrol Dust Tool

Dust tool is a free of charge configuration utility for Sintol series devices.

The software can be downloaded here: