Higher Safety with Quick Response Time

When protecting critical machinery or high-risk areas from fires, the response time of a fire protection system is essential. The quicker a fire can be detected and extinguished, the less damage it will cause, production losses can be kept to a minimum and employee safety will be greatly enhanced.

By using an appropriate fire protection system with a quick response time, the risk for the fire to be spread to other areas can also be minimized.

Conventional sprinkler or water mist systems gives a good overall protection of a facility or a building, but is not ideal for protection of high-risk areas or critical machines. By the time a sprinkler system is activated, the fire has most likely already caused damages and possible even spread into other areas.

The purpose of a Quick Suppression System is to act quickly enough to avoid or significantly reduce damages and production downtime, as well as preventing the fire from escalating and spreading into other areas, and to increase personal safety.

What is a Quick Suppression System?

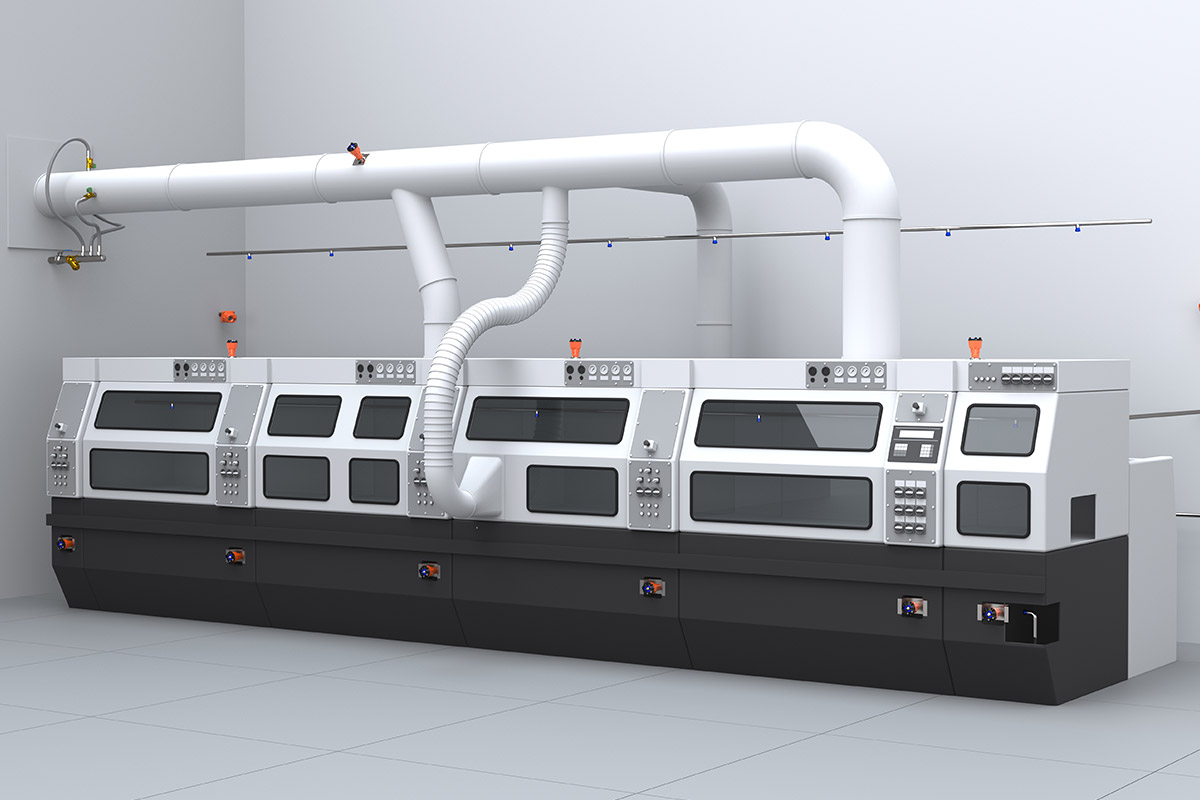

A Quick Suppression System is a Fixed Automatic Discharge Fire Suppression System, including flame detection, water mist suppression and control system, with strict demands on quick system response times and fast extinguishing performance.

The system is designed for quick detection and suppression of fires/flames around critical machinery or high-risk areas.

The Quick Suppression System in its design is similar to a Spark Detection System, which combines detection, extinguishing and a control panel. The spark detection system however, is designed to detect and extinguish ignition sources preventing a fire, whereas the Quick Suppression System is designed to detect and extinguish fires/flames at a very early stage.

Firefly Quick Suppression System

The Firefly Quick Suppression System is based on Firefly’s own high performance flame detectors and efficient water mist systems. Firefly has a number of different flame detectors with different characteristics, to match the conditions of each application.

The Firefly water mist suppression systems have remarkable flame suppression capabilities, utilizing a very small amount of water. The unique design of the hydraulic system enables a very quick system response time.

The complete system response time for a Firefly Quick Suppression System is normally as short as 1-3 seconds. Even shorter response times can be achieved for special applications.

The Firefly Quick Suppression System uses the same control panel as the Spark Detection System, so the two systems can easily be integrated, combining prevention and protection, to achieve an optimized system functionality.

Examples of applications where Firefly Quick Suppression Systems are used

- Protection of IR Dryers in Paper Machines

- Planers and Moulders

- Wood Panel Presses

- Oil Pump Rooms

Test Protocol for Quick Suppression Systems

The test protocol for Quick Suppression Systems is called ‘DFL TM170307-1261 – Quick Suppression

Systems for certain high-risk areas typically found in industry applications’. It has been developed by DFL, an ISO/IEC 17025 certified test facility, accredited to conduct full scale fire-tests.

This test protocol is based on CEN/TS 14972:2011, Appendix B, with full fire tests for both solid fuels and liquid fuels. It has very strict requirements on the maximum accepted extinguishing times and it covers the complete system with detection, extinguishing and control system. The test protocol also specifies the maximum allowed response time (‘Complete System Response Time’) as short as 5 seconds on most tests.

The test protocol specifies a pre-burn time of 1 minute, with heptane, to be used for all fire tests. This is to test the system at “worst-case scenarios” and make sure that the fire is deeply developed before extinguishing action is started. In reality the extinguishing action is activated in just a few seconds with a Quick Suppression System, which will make it easier to extinguish a fire.

All this together makes the DFL TM170307-1261 a very conservative and a highly demanding test protocol.

The test protocol includes 9 different test series for different applications as well as comparison test with other fuels and response tests of the system, to verify the Complete System Response Time.

The test protocol also requires that the installation of a Quick Suppression System must be preceded by a Risk Assessment of the application.

Firefly – The world’s first third party approved Quick Suppression System

In April 2017 – Firefly performed tests according to DFL test method no. DFL TM170307-1261. The tests were conducted at DFL, an ISO/IEC 17025 certified test facility and witnessed by several insurance companies.

During the tests in April Firefly did fire tests in test series 1,2,4,5,8 and 9 and all tests were successfully performed and approved.

About ProDetec

ProDetec was established in 2003 and is a quality ISO9001 company with an extensive client base throughout Australia and New Zealand. ProDetec is focused on client satisfaction and process efficiency. We have in-house and on-site service & commissioning capabilities and a team of qualified engineers.