Description

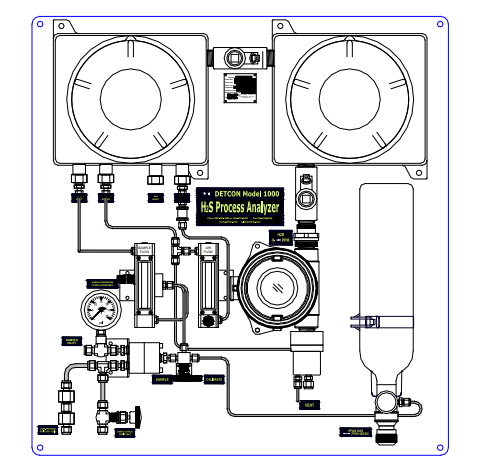

Technical Description – Model 1000 H2S Analyser

The Detcon Model 1000 Series H2S Process Analyzer is a 110/220VAC or 24VDC powered analyser that provides a select gas sample mixture to an on-board DM-624 H2S gas sensor assembly. The range of gas analysis can span from 0-10ppm up to 0-5%. The range of analysis is determined at time of order.

A Closer Look

When located outdoors, the H2S Process Analyser package should be appropriately covered from direct weather exposure. The Model 1000 Series H2S Process Analyzer can optionally be ordered with a full NEMA 4 enclosure.

The “Power Supply” enclosure on the upper right side of the unit houses a 24VDC power supply, a 24V DCDC Converter, and a terminal PCB labelled for all input and output field wiring. The “Pump/Flow” enclosure located on the upper left houses an air dilution pump, an activated carbon scrubber, and optional air flow fault and sample flow fault alarm PCB’s.

The analyser requires a constant, liquid-free, 10±2psig sample pressure, which is provided by the customer or may be supplied by Detcon as a separate gas sample handling system.

The on-board gas sample conditioning system includes a stainless-steel pressure gauge (0-30psig), and a Genie membrane filter to provide the analyser with absolute condensate liquid protection. On the bypass port of the Genie membrane filter, a 15-psig over-pressure relief valve and flow control valve are also provided. The flow control valve can be used as a continuous sample bypass and liquid exhaust vent. A dedicated air and sample mixture is maintained via 2 control valves and 2 rotameters. The Sample is then delivered to the Model DM624 H2S gas sensor for analysis. An optional on-board span gas cylinder is provided for span calibration, and a selectable 3-way valve is provided for manually switching between sample monitoring and span calibrations. An optional Acetic Acid Bubbler apparatus is available to scrub the gas sample when it contains high concentrations of VOC’s as found in some injection spray H2S scavenger chemistries. An optional live heat tracing feature may be used to prevent condensation after the Genie Membrane Filter.

The Specs at a Glance

| Sensor Type | Electrochemical cell |

| Measurement Range | 0-10ppm H2S, up to 0-5 % H2S |

| Accuracy/Repeatability | ±10% of reading or ±0.5ppm, whichever is greater |

| Response/Clearing Time | T80 < 1 minute |

| Operating Temperature | -40°F to +122°F: -40°C to +50°C |

| Outputs | Linear 4-20mA DC; RS-485 Modbus™; 3 relays (alarm 1, alarm 2, and fault), Contacts rated 5 amps |

| Input Voltage | 110~220VAC; 18~36VDC |

| Power Consumption | 700mA (16.8 watts) |

| Electrical Classification | Non-Hazardous Area |

| Sensor Life/Warranty | Sensor: 6-month conditional warranty; Transmitter: 2 year warranty |

| Analyzer Weight | 70 lbs. |

| Dimensions | 29” X 29” X 8” |

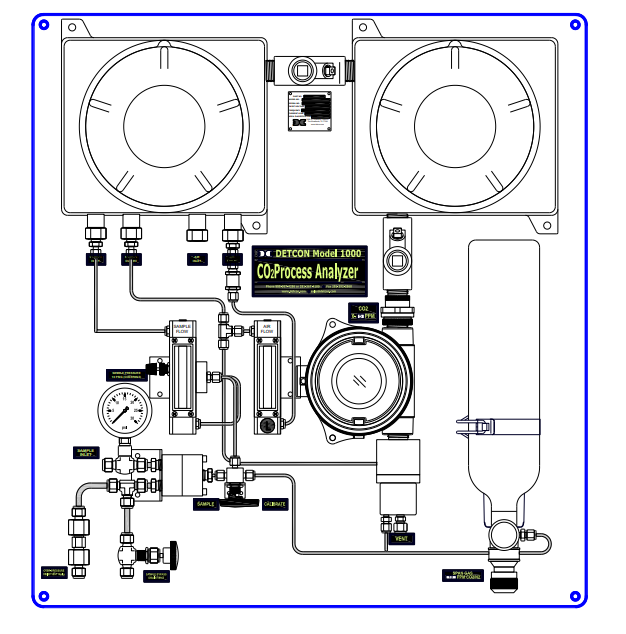

Technical Description – Model 1000 CO2 Analyser

The Detcon Model 1000 Series CO2 Process Analyzer is a 110/220VAC or 24VDC powered analyser that provides a select gas sample mixture to on-board IR-640/IR-642 CO2 gas sensor assemblies. The ranges of analysis are determined at time of order.

A Closer Look

When located outdoors, the CO2 Process Analyzer package should be appropriately covered from direct weather exposure. The Model 1000 Series CO2 Process Analyzer can optionally be ordered with a full NEMA 4 enclosure.

The “Power Supply” enclosure on the upper right side of the unit houses a 24 VDC power supply, a 24V DCDC Converter, and a terminal PCB labelled for all input and output field wiring. The “Pump/Flow” enclosure located on the upper left houses an air dilution pump, an activated carbon scrubber, and optional air flow fault and sample flow fault alarm PCB’s.

The analyser requires a constant, liquid-free, 10±2 psig sample pressure, which is provided by the customer or may be supplied by Detcon as a separate gas sample handling system.

The on-board gas sample conditioning system includes a stainless-steel pressure gauge (0-30 psig), and a Genie membrane filter to provide the analyser with absolute condensate liquid protection. On the bypass port of the Genie membrane filter, a 15-psig over-pressure relief valve and flow control valve are also provided. The flow control valve can be used as a sample bypass and liquid exhaust vent. The IR-640/IR-642 CO2 gas sensor measures the sample directly, except in units that utilize dilution. The CO2 sample flow is maintained by a constant flow ‘Mass Flow controller’ and an associated rotameter, while airflow is maintained by a control valve rotameter. A 3-way valve is provided for manually switching between sample monitoring and span calibrations.

The Specs at a Glance

| Sensor Type | Non-Dispersive Infrared (IR-640/IR-642 CO2 Sensor) |

| Measurement Range | 0.3% up to 5% (IR-640 CO2 Sensor)

10% up to 100% (IR-642 CO2 Sensor) 10% up to 100% (IR-640 CO2 Sensor with air dilution) |

| Accuracy/Repeatability | ± 5% Full Scale (IR-640/IR-642/IR642 CO2 Sensor) |

| Response/Clearing Time | T50<30 seconds, T80<60 seconds (IR-640/IR642 CO2 Sensor) |

| Operating Temperature | -40°F to +122°F: -40°C to +50°C |

| Operating Pressure: | Inlet: 10±2psig Outlet: Ambient±1psig |

| Outputs | Linear 4-20mA DC; RS-485 Modbus™; 3 relays (alarm 1, alarm 2, and fault), Contacts rated 5 amps |

| Input Voltage | 117~220VAC; 18~36VDC |

| Power Consumption | 925mA max (22.2Watts), 300 mA nominal (7.2 Watts) @ 24VDC |

| Electrical Classification | Non-Hazardous Area |

| Sensor Life/Warranty | Sensor: 5-year conditional warranty. Transmitter: 2-year warranty (IR-640/IR-642 CO2 Sensor) |

| Analyzer Weight | 75 lbs. |

| Dimensions | 29” X 29” X 8” |