Bio Energy – Pellet Production and Bio Gas Plants

As the Bioenergy industry grows, so do its fire problems. There are several high-risk zones in which fires or dust explosions may arise in pellet production and in power plants. There is also a need to utilise the Biogas from Poultry and Pig Farms, correct measurement of the digester gas is essential for efficient use of this energy.

Headlines about fires in pellet plants are unfortunately common. It is however no coincidence that the wood pellet industry is particularly exposed to fires. In a pellet manufacturing process there are several high-risk zones where fires or dust explosions can occur. Furthermore, the pellet process environment is very demanding.

Detecting the right hot particles is critical when it comes to protecting Filters and Silos. You need to detect down to the right ignition temperatures to ensure your plant is protected.

Because a fire in a belt conveyor can spread very rapidly, a fast acting fire protection system that also can withstand the tough conditions in and around a belt conveyor is required

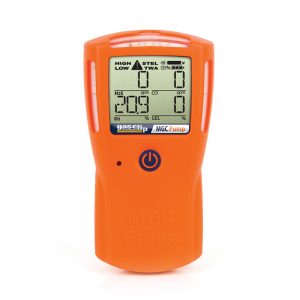

ProDetec can offer our customers innovative portable gas detectors that offer greater reliability, improved productivity, and better cost-efficiency to protect your workers from potential gas hazards. These gas detectors can be readily calibrated and tested on site with the aid of Automated Calibration and Bump Testing Stations

At ProDetec we can supply specialised gases and gas mixtures to meet various and specific requirements. We work with you to understand your application and analyse your consumption patterns. This way we can offer the correct cylinder size that maximises your efficiency while minimising costs.

Digester gas, a term with a somewhat negative connotation, has become an important component of alternative energy generation in some countries. Within the framework of the energy transition, digester gases from sewage treatment plants and waste recycling plants are becoming increasingly important. The gas analysis component of the related plant technology plays an important role both for process monitoring and for safeguarding the plant components operated with the digester gas. The INCA gas analyser technology is specially tailored for this.

Dust explosions can occur frequently in industrial processes where combustible material is transported/ pneumatically or mechanically conveyed, heated, filtered, spray dried, milled and stored