Description

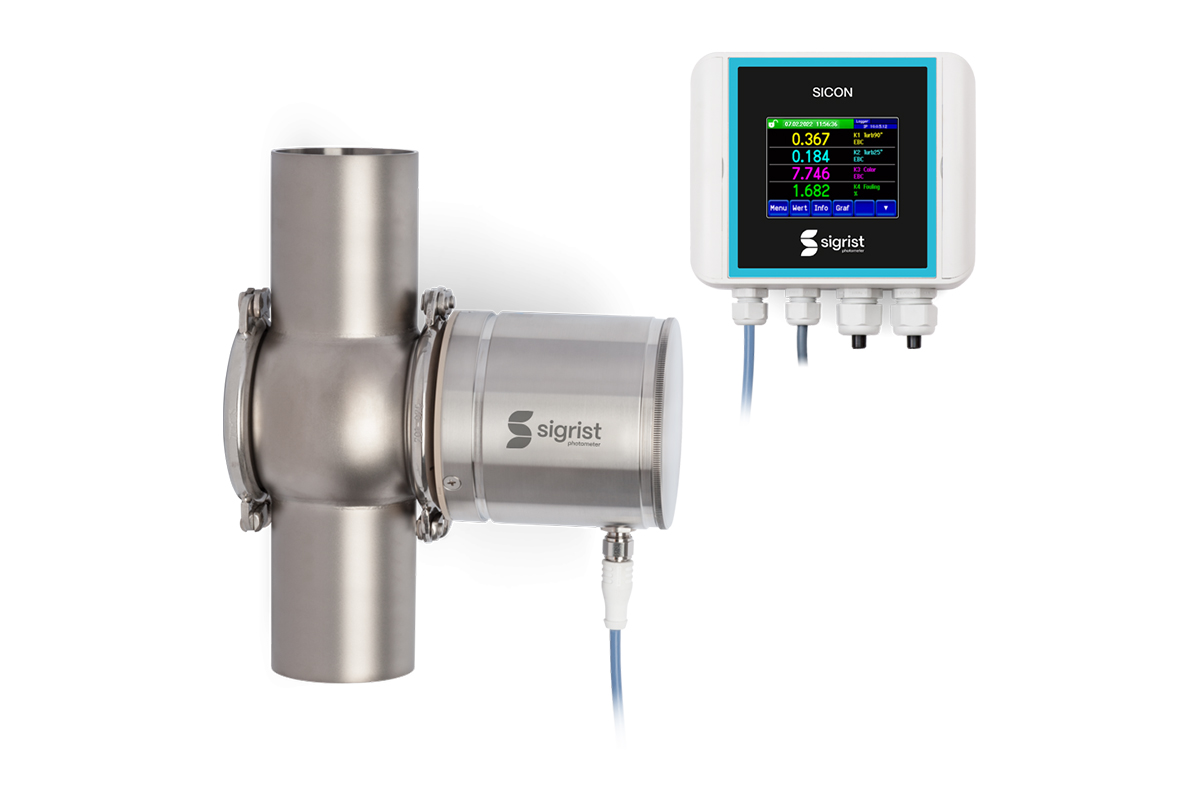

Technical Description – TurBiScat

The measurement of turbidity in the brewing industry and specifically the monitoring of filtration in the brewing process is firmly connected with the name SIGRIST. SIGRIST offers a full range of optical measuring instruments covering all important applications in breweries – right from the brew house through to the laboratory.

Monitoring wort turbidity at the lauter tun and at the mash filter Due to variation in quality of the raw materials, it is important to obtain information on the quality of the wort at an early stage. It makes sense to carry out this monitoring with a forward scatter angle photometer, i.e. the TurBiScat 25° (recommendation EBC/MEBAK) or a dual-angle measurement with the TurBiScat 90/25. If rising turbidity values are seen quickly, a process adjustment can then be carried out at the mash stage. During the subsequent brewing process, measures can be taken in advance to filter the problematic brew.

A Closer Look

Applications

- Filtration monitoring in beverages such as beer, fruit, juices, spirits

- Supervision of centrifuges, separators, whirlpools in the beverage industry

- Turbidity measurement in oils, sugar solutions, food

- Purity control in chemical and pharmaceutical processes

Industries

- Beverage

- Food

- Chemical

- Pharmaceutical

Advantages

- Seal less design, maintenance-free

- Extended sensor check function with fouling control

- Colour-compensated, 90° / 25° dual-angle measurement

- Optional colour measurement at 430 nm

- Quick adjustment with secondary standard

- Control unit with colour touch screen display

- Variable display of measuring data graphs, process performance

- Smooth system integration using various

- communication interfaces

Specs at a Glance

| Measuring principle: | 90° / 25° Scattered light |

| Wavelength turbidity: | LED 650 nm |

| Wavelength colour (optional): | LED 430 nm |

| Measuring span turbidity: | 0 .. 1’000 EBC

0 .. 4’000 NTU 0 .. 69,000 ASBC |

| Measuring ranges: | 8, freely programmable |

| Resolution: | 0.001 EBC / 0.07 ASBC |

| Measuring span colour: | 0 .. 50 EBC / 0 .. 25.4 SRM |

| Installation: | In-line housing Varivent® or compatible |

| Material sensor head: | Hastelloy® C-22® |

| Material housing: | Stainless Steel 304 / 1.4301 |

| Windows: | Sapphire |

| Sample temperature: | −10 .. +100 °C / +14 .. +212 °F +180 °C / +356 °F with cooling option |

| Cleaning: | CIP / SIP compatible up to +120 °C / +248 °F @ 2 h |

| Pressure: | 1 MPa (10 bar) / 145 psi in standard Varivent® housing Up to 4 MPa (40 bar) / 580 psi on request |

| Ambient temperature: | −10 .. +50 °C / +14 .. +122 °F |

| Ambient humidity: | 0 .. 100 % RH |

| Protection degree: | IP66 |

| Control unit: | SICON |

| Power supply: | 9 .. 30 VDC |

| Power consumption max.: | 8 W (with instrument) |

| Display: | 1/4 VGA, 3.5“ |

| Operation: | Touchscreen |

| Ambient temperature: | −10 .. +50 °C / +14 .. +122 °F |

| Ambient humidity: | 0 .. 100 % RH |

| Protection degree: | IP66 |

| Outputs: | 4 × 0/4 .. 20 mA, galv. Separated 7 × digital |

| Inputs: | 5 × digital, freely configurable |

| Digital interfaces: | Ethernet, microSD-card, Modbus TCP |

| Optional modules (max. 2): | Profibus DP, Modbus RTU, HART 4 × 0/4 .. 20 mA outputs, galv. Separated 4 × 0/4 .. 20 mA inputs |

Calibration Certificate

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

EU Declaration of Conformity

Hover Box Element

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Sigrist Communication Software

Vx29 is the current software controlling communication between the analyser and the SICON.

Check for updates periodically. Sign up to our newsletter for notifications of software updates.

The control unit SICON uses state-of-the-art touch screen technology with colour display. It allows simple operation using logical menu guidance. The user can select how results are displayed, either as plain values, graphs or historical data, including the indication of system and alarm status.

The control unit SICON offers all possibilities of full system integration using various interface options. A SD card is standard and can be used for data logging with almost unlimited storage capacity.

The SICON is available as a control unit for a single instrument, or the SICON M Control Unit which allows simple operation of several instruments up to a maximum of 8 measuring channels.